PRODEM: PROduction on DEMand

Workwear made to order

At Lindström, we don’t produce workwear for shelves. We produce garments only when you need them. This reduces waste while allowing us to pay extra attention to quality, durability and timely delivery. By producing close to our customers, we avoid unnecessary transportation and stockpiling.

What is PRODEM?

Welcome to PRODEM – Lindström’s own production model for workwear manufacturing. Instead of producing large batches based on forecasts, we manufacture garments only after receiving confirmed orders. This means no extra garments sit in storage, and no resources are wasted. Our production follows lean manufacturing principles, with every step designed for efficiency, accuracy and flexibility.

Whether you need a small delivery or a quick replacement, we are ready to respond, even to quickly changing needs. Located close to you, we can deliver faster, reduce emissions and avoid long-distance shipping.

Prodem in figures (2024)

In 2024, the average order quantity was 4.6 pcs/order, and we delivered the garments in a total of 5-7 days.

Why PRODEM matters to you:

By making workwear on demand, we can meet your needs with flexibility. Yet, we keep the environmental impact low. Once a customer order comes in, it signals a start of production in the nearest PRODEM facility.

Fast when it matters

Quick turnaround for both big and small orders – no more waiting around. This means your employees get the right garments on time, every time.

Only what you need

Because we produce only what is ordered, you avoid the costs and risks tied to large stock levels. Just reliable delivery at a predictable price.

A team that cares

Our teams work in small groups, trained to handle multiple steps. When our teams are engaged, your workwear is made with care and precision.

Quality you can trust

Every order is carefully produced and checked based on strict quality standards. The result: durable garments that stand up to everyday use.

Close to you

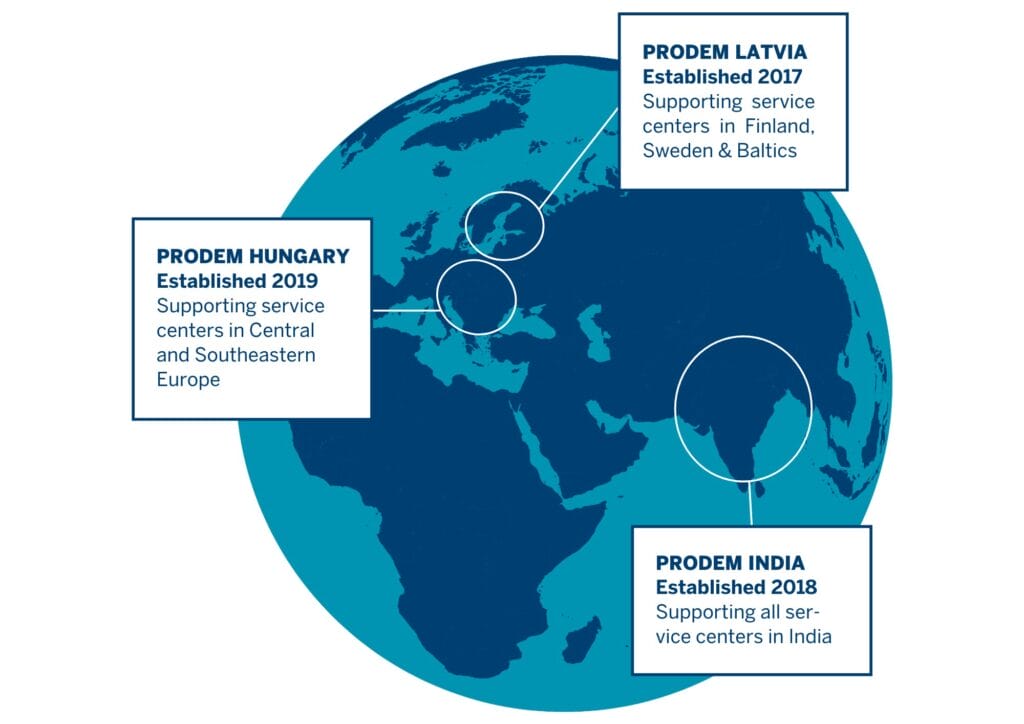

We currently operate PRODEM factories in Latvia, Hungary and India. Each location serves its nearby regions, helping us deliver quickly while keeping transport distances short.

PRODEM Latvia

Our Latvia facilities serves Northern Europe since 2017, providing quick efficient and service. Located close to our customers, the delivery time is short, while keeping the transport emissions low.

“Our factory is quite a unique place. We specialise in the rapid production of small-scale orders, catering to tight timelines with exceptional efficiency. Normally in garment manufacturing, you have lead times of 40 to 60, or even 100 days, and order sizes in hundreds and even thousands at the same time. At PRODEM, we can do it a lot faster; in a matter of a few days.”

Gusts Dzenis, Managing Director of PRODEM Latvia

PRODEM Hungary

Our workwear manufacturing strategy was brought to Hungary in 2019, through retrofitting an existing facility and training the team according to the PRODEM concept. Today, this location serves Lindström customers in Central and Southeast Europe.

“The idea that garment manufacturing can be done only on an acceptable price level only in countries with extremely low labour costs and in underdeveloped working environments is not true anymore. The focus in this industry is switching towards garments with higher quality level, manufactured in an effective and sustainable manner and in much more developed working environments.”

Zsolt Keresztes, Managing Director of PRODEM Hungary

PRODEM India

Our garment manufacturing facility in India was started in 2018. This state-of-the-art facilities is located in Mumbai and serves Lindström customers of India region.

“Our Production Model is designed to deliver garments with High quality standards in short lead times that helps eliminate garment stocks. Our Operations are very flexible and efficient that supports Dynamic Supply Chain model of Lindström’s Operational and Environmental strategies.”

Mehul Sahu, Head of PRODEM India

Peek into our factory in Tukums, Latvia

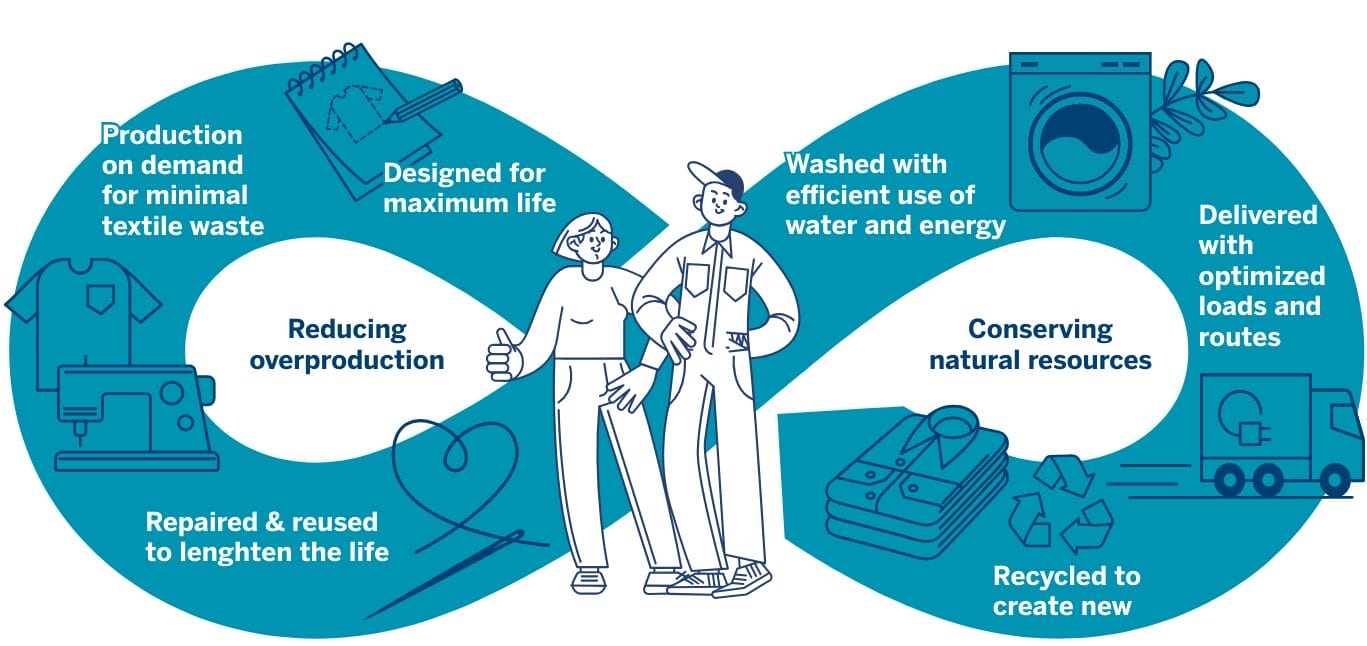

Sustainability in every step

PRODEM is more than a manufacturing model; it’s a step towards a more sustainable textile industry. By only producing on demand, we prevent overproduction and waste. It serves as an effective way to eliminate the textile obsolete risk in the stocks. Each step, from sourcing durable, certified materials to recycling production scraps, is designed to reduce our footprint.

No overproduction

We produce garments on demand, cutting excess stock and waste. Lean methods inspired by the Toyota Production System help reduce resource use in the process.

Recycling materials

During production, fabric scraps and offcuts are collected and recycled. Trusted partners SK-Tex in Slovakia and Texool Refashion in India handle even complex materials.

Durable materials

We use high-quality fabrics that stand up to daily use. Fewer replacements are needed, and repairs come first; extending each garment’s life and reducing textile waste.

Renewable energy

All PRODEM factories now run on 100% renewable electricity. 25% is generated by our solar panels. The rest is certified green energy, helping us meet our Net-Zero goals.

PRODEM 2.0

We are always looking for ways to improve how PRODEM works. Our focus is on making processes simpler, more efficient and better prepared for the future. This includes standardising designs to speed up production, adding automation to support selected production steps, testing where robotics, AI or 3D tools can help, as well as keeping our people trained and skilled as new technologies develop. Will you join our journey towards more circular workwear design?

More stories about PRODEM

Our PRODEM factories run on 100% renewable energy. Learn how our on-demand production model benefits customers and our 2030 climate goals.

Prodem Hungary is one of Lindström’s three production-on-demand factories, where sustainability permeates all parts of the operation.

PRODEM is a customer-focused textile manufacturing facility created to meet the constantly changing demands of customers.

In this article, our professionals share a couple of examples on how we make our service both sustainable and cost-efficient.

PRODEM or PROduction on DEMand is a dynamic customer-driven textile manufacturing practice in response to ever-changing demands.