Changing room design in food manufacturing: 6 top tips

Changing rooms are often overlooked in design, but did you know it is one of the most important rooms to consider in food production?

Learn the best practices to ensure hygiene and safety in changing rooms!

Changing rooms play an essential role in the food industry

Any food processing facility will need a changing room, as they provide a place for workers to change into clean and protective clothing before entering the production area. Changing rooms also helps to prevent cross-contamination and ensure compliance with food safety standards.

However, designing changing rooms for food manufacturing facilities can be challenging. They need to meet the specific needs and preferences of employees, as well as the facility’s requirements and industry regulations. This article provides practical guidance on how to design changing rooms for food production employees based on best practices and industry examples.

6 things to consider in your changing room design

When designing changing rooms for food processors, consider these things:

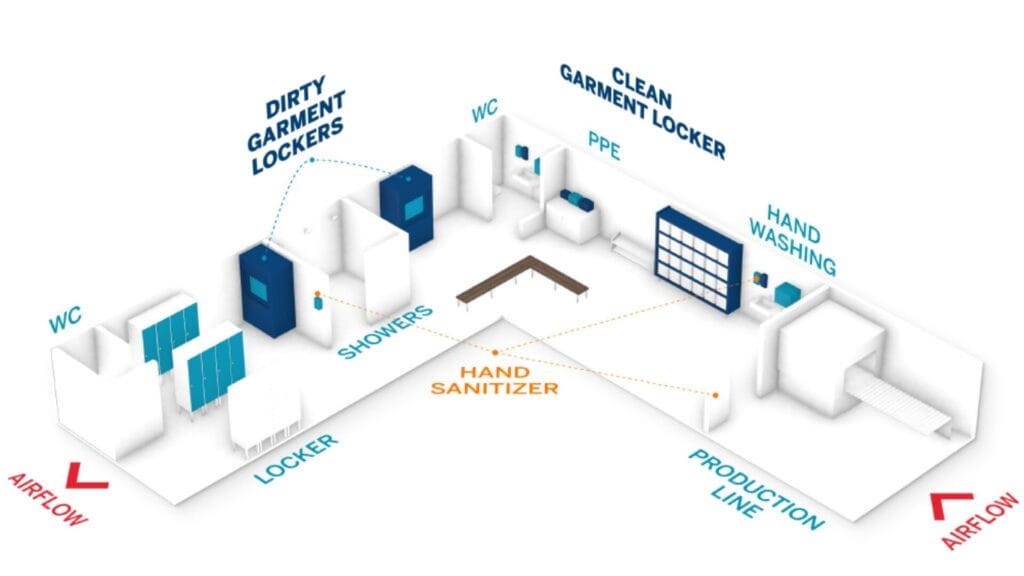

- Size and layout

Pay attention to the number and flow of workers and that the size and design of the changing room is adequate for them. This will allow for easy access and movement. - Location and orientation

The changing room should be close to the production area but separated by a physical barrier, such as a door or a corridor for preventing contamination. - Ventilation and lighting

There should be sufficient air and brightness in the changing rooms to maintain a comfortable and hygienic environment. - Storage and disposal of personal and protective clothing

These storage spaces should be clearly marked and separated. Provide enough space and facilities for workers to store their belongings and dispose of their used garments. - Hygiene and sanitation

Changing rooms should be cleaned and disinfected regularly. Provide hand washing and drying facilities for workers. - Safety and security

Equip your changing rooms with fire alarms, emergency exits, and locks. The room entrances can be monitored with cameras or staff to ensure the changing rooms are always safe.

Workwear and how to store it in the changing room

A key design consideration for storing workwear in the changing room is preventing cross-contamination between clean and dirty garments. Keep your workwear sanitary by:

- Having separate lockers or shelves for clean and dirty clothing, and a clear labelling system for them.

- Installing a barrier or a partition between the clean and dirty areas of the changing room. Ensure that workers do not cross or mix them.

- Providing bins or bags for workers to dispose of or collect their dirty clothing. Empty and sanitize the bins at regular intervals.

- Setting up hooks or hangers for employees to hang clean clothing. With these they can avoid folding or stacking them on the floor or on benches.

Another design consideration for storing workwear in the changing room is to ensure the security and convenience of the workers. Achieve this by adding:

- Lockers or shelves that are spacious enough to accommodate the workers’ personal belongings and workwear and that can be locked with a key, a code, or a biometric system.

- Mirrors, lighting, and ventilation in the changing room, and maintaining a comfortable temperature and humidity level.

- Hand sanitizers, roll towels, and wipes in the changing room. Encourage workers to use them before and after handling their clothing.

- Clear instructions and signs in the changing room that help educate workers on the proper use and storage of their workwear.

Read more about the key role of workwear in the prevention of cross-contamination and related issues in changing rooms in our comprehensive guide to hygienic workwear in the food industry.

Successful case examples and their best practices:

Here are 3 examples of successful changing room designs from different sectors and countries:

Dairy sector

A Latvian cheese factory featured a linear layout of their changing room, with separate entrances and exits for workers. There is a clear division between the dirty and clean zones.

The changing room is equipped with lockers, benches, hooks, and bins for personal and protective clothing. The room also has hand washing and drying stations.

Meat sector

A slaughterhouse in the Czech Republic designed its changing room with a circular layout. It has a central corridor connecting the production area with the changing room.

There are separate sections for male and female employees, as well as for different types of clothing, e.g., outerwear, footwear and headwear. The changing room also has showers, toilets, and sinks for washing and sanitation.

Bakery sector

An English bread factory implemented a modular layout for its changing room. It has individual cubicles that can be adjusted to the changing rooms’ size and shape.

There are lockers, mirrors, and shelves for employees to store and organize their clothing, as well as hand sanitisers and paper towels to promote hand hygiene.

Ensuring compliant changing rooms through the design

Changing rooms are an important part of the food processing industry, as they help to ensure the hygiene and safety of the workers and the products. Designing changing rooms for food manufacturing employees can be a complex task, as it involves balancing the needs and preferences of the workers, the requirements of the facility and the regulations, and the available space and resources. However, by following some key design considerations and best practices and learning from the examples of other food processors, it is possible to create a changing room that is functional, comfortable, and compliant.