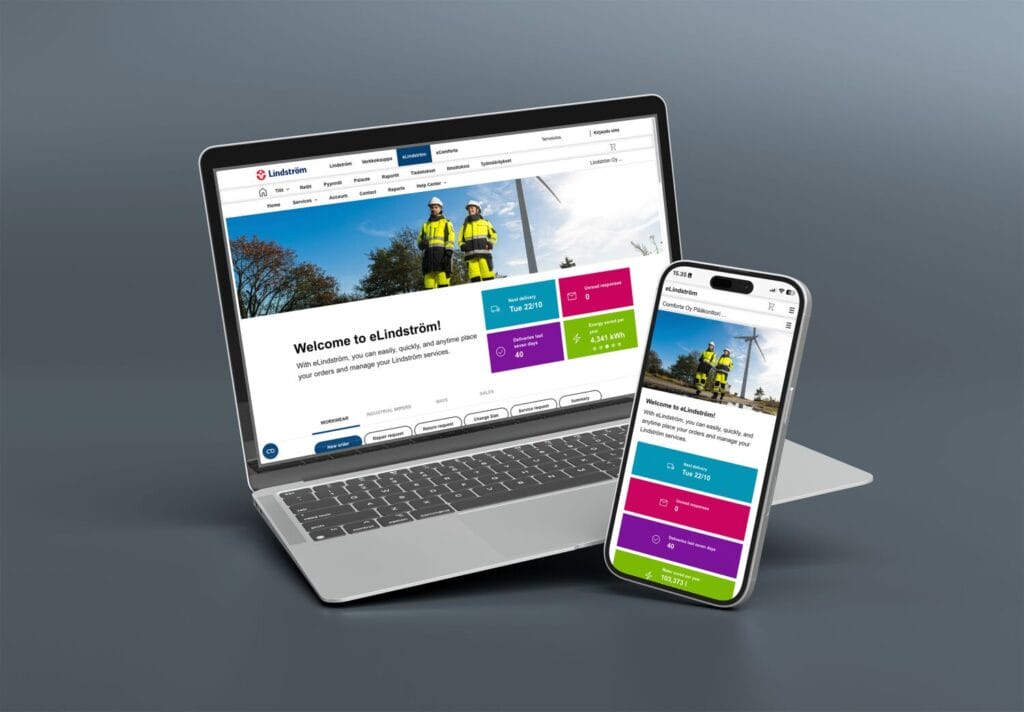

Introducing Workwear Alarm for hygienic and safe workwear

Tired of missing workwear? Worried about hygiene compliance? Managing workwear in regulated industries like food production is challenging enough—garment loss and non-compliance shouldn’t add to your list of worries.

That’s where Workwear Alarm comes in. This new loss prevention system ensures employees don’t take garments off-site and that all workwear is professionally cleaned and maintained. No more chasing lost uniforms, risking hygiene breaches or costly disruptions: just seamless workwear tracking and total peace of mind.

Ilari Laitinen, Service Designer at Lindström, explains how it works, who it’s for, and the benefits it delivers.

Workwear Alarm, explained:

How Workwear Alarm keeps workwear where they belong

Workwear Alarm relies on the RFID technology embedded in each Lindström garment.

If a tagged garment is removed from a designated area, the system triggers a light and/or sound alarm. Ilari notes:

Workwear Alarm goes hand in hand with our digitally supported workwear. The unique RFID tags in every Lindström garment make this service possible.

RFID scanning

Detects Lindström garments 24/7.

Alarm light

Triggers a light or sound alarm when garments leave the area.

Security response

Customers can train their teams to react appropriately.

Data reporting

Logs all events, generating ready reports.

The basic Workwear Alarm package includes a system unit, an alert module (with light and sound capabilities), and an RFID antenna, with the option to expand for larger areas. For safety reasons, the alert module uses only the light function indoors, while sound alerts can be enabled for outdoor use. The system is quick to install, integrates into your existing workflow, and requires minimal technical expertise.

Ilari emphasises that Workwear Alarm requires active involvement from customers. “The system collects data and flags garments leaving the premises, but it’s up to customers to decide how to act on that data.”

Often, misunderstandings arise when employees aren’t sure how the Lindström workwear rental service works. That’s why employee awareness is crucial—teams should understand that garments are not meant to be taken home. If security staff are involved, they should receive proper training on how to handle interventions.

Pilot insights: Workwear Alarm reduced garment loss by 60%

In 2024, our workwear team piloted Workwear Alarm at a food manufacturing company in the Czech Republic over a six-month period, testing its reliability and learning a lot along the way. “Launching Workwear Alarm is a huge milestone because we developed this technology in-house, and the pilot confirmed its feasibility,” says Ilari.

For instance, a storm-induced blackout temporarily disrupted data collection at the pilot site, but the system quickly resumed full functionality remotely, retaining all critical data.

The pilot also showed how effectively Workwear Alarm can solve the customer’s garment loss challenge:

In the first week, the system was up and running, but employees weren’t aware of it and security wasn’t responding. At that point, up to 160 garments were moving in and out daily. Once the system was fully launched, employees were informed and security began responding to alerts. Then that number dropped to just 20 garments a day.

Top benefits of Workwear Alarm

Prevent garment loss

If you’re spending too much time tracking missing garments, Workwear Alarm provides a simple solution. It reduces the risk of garments being taken off-site and helps you spot where things might be going wrong.

“A common sign of garment loss is employees complaining about a lack of clean workwear, leading the customer to order unnecessary replacements,” says Ilari.

When Lindström garments go missing, customers are responsible for replacement fees. But with Workwear Alarm, you gain the transparency needed to track your garments and ensure they’re always available, helping you cut down on reimbursement costs for missing items.

Comply with hygiene standards

While garments may go missing, it doesn’t always mean they’re stolen. “They could be washed at home—or not washed at all—putting cleanliness at risk and causing serious consequences,” says Ilari. Every time garments are taken home and returned to the production area, it compromises hygiene and production standards.”

Workwear Alarm ensures garments are professionally cleaned and worn only on-site. It also keeps a clear, auditable record of garment handling, ensuring compliance with hygiene regulations and industry standards like the International Featured Standard (IFS).

Beyond meeting regulations, Workwear Alarm also shows your commitment to consumer safety and product quality.

Keep employees safe

Workwear Alarm prevents employees from washing their workwear at home, ensuring the garments’ protective features stay intact, which is crucial in high-risk industries. “In environments like factories where employees do welding, garments often have flame-retardant treatments that need reapplication during professional washing. Without this, employees’ safety is at risk,” says Ilari.

When garments are used as instructed, Lindström ensures they are cleaned properly and on time, helping you meet safety regulations and protect employees from workplace hazards. Regular checks and maintenance also prevent everyday wear and tear from compromising safety.

Improve sustainability

Sustainability is increasingly important to our customers, and we’re committed to helping our customers grow sustainably in everything we do. Workwear Alarm supports this by extending the lifespan of garments. By ensuring proper cleaning and maintenance, you can reduce the need for frequent replacements.

Using the right detergents and processes also helps preserve garments, minimising waste and supporting your sustainability goals.

Combining workwear services for better tracking

As a company using Lindström workwear, you can maximise the value of your service by bundling digital solutions like Workwear Alarm with other add-ons, like Workwear Flex.

Ilari explains: “Workwear Flex is a garment lending station—similar to a library— where employees borrow and return garments. By integrating Workwear Alarm with Flex, you add an extra layer of tracking, ensuring garments are always where they should be. This combination gives you valuable data and more control over your workwear management.”