Study reveals hygiene risks in food industry workwear practices

A study conducted by market research company Norstat for Lindström surveyed 940 food industry workwear users in 11 European countries. The findings suggest food industry hygiene practices may be weaker than expected, posing potential food safety risks.

Hygiene risks of home washed workwear in food industry

The survey revealed that home washing of workwear remains common, even when employers provide a professional washing service. A significant portion of users, 73%, had been taking workwear home for washing. More concerningly, 64% of those washing at home reported doing so at temperatures below 70°C – insufficient to effectively eliminate harmful bacteria. Although ironing can also significantly reduce bacterial presence, fewer than one-third of respondents stated that they always iron their garments.

The primary motivation for home washing was concern over hygiene and cleaning quality, with 18% believing that home washing delivers better results than industrial laundering. Additionally, 20% cited a lack of clean workwear as the reason for bringing garments home.

” These findings are concerning. Home laundering does not follow proper washing procedures and increases the risk of cross-contamination. Garments may be exposed to household bacteria, allergens, and any foreign object which should not end up in the food processing area and finished products,” says Csilla Kovács-Rahói, International Account Manager and food industry expert at Lindström.

73%

have brought workwear home to wash

64%

wash the workwear below 70 degrees

24%

have taken their workwear outside work premises

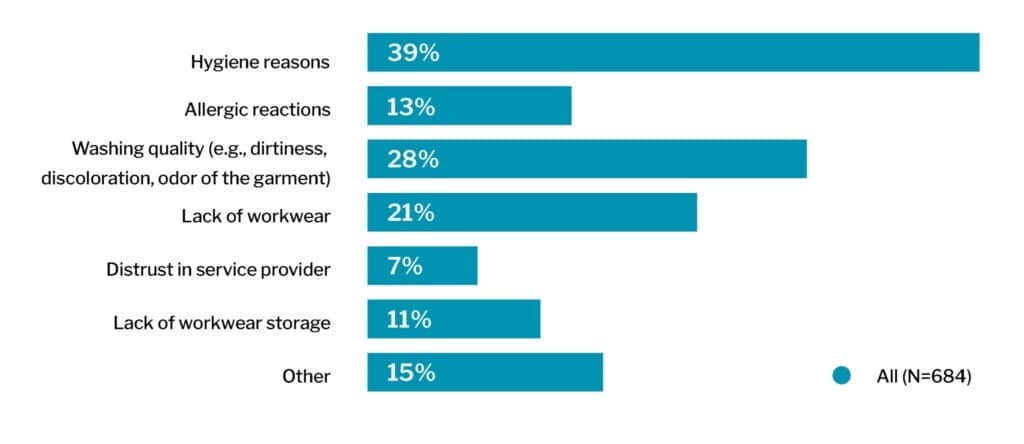

Main reasons for washing workwear at home

Workwear worn outside the workplace increases contamination risk

The survey also found that one-third of employees are unaware of the hygiene standards their facility must follow. Furthermore, 24% admitted to wearing workwear outside the workplace, increasing the contamination risk.

“We suspected the issue of workwear leaving production premises was more widespread than acknowledged. Similar patterns emerged during the development of our Workwear Alarm solution – an intelligent system that uses digital technology to detect and alert if garments are taken outside designated areas,” adds Kovács-Rahói.

As food safety continues to be a global concern, these findings highlight the need for stronger, standardised practices in workwear management to reduce hygiene risks in food industry.

“Workwear hygiene begins with design. Garments should be durable and free from features that pose contamination risks. Damaged clothing must be repaired promptly, as a torn sleeve or missing fastener can harbour bacteria or even end up in the food. Home washing is strongly discouraged due to the many contamination risks during laundering and transport. It also lacks of quality control and repairing opportunities,” Kovács-Rahói says.

The study clearly highlights a widespread gap between best practices and everyday realities in food industry workwear hygiene. As the risk of cross-contamination remains a critical concern for food safety, it is essential to reassess these hygiene practices in food companies.

More information about the study

Leena Kähkönen

Manager, External communication

+358 50 58 68 582

About the study

The survey was conducted by Norstat, the leading independent European data collector for market research in February 2025. It covered 11 European countries: Bulgaria, Croatia, Czech Republic, Estonia, Germany, Hungary, Latvia, Lithuania, Romania, Slovakia, and Türkiye.

A total of 2,276 employees who use workwear participated in the survey, of which 940 work in the food industry. Within the food industry group, the majority of respondents were permanent employees (76% of participants), and women made up 61% of this group.