Supplier spotlight: Kleen-Tex drives sustainability and transparency

Highlights:

| 30-year partnership between Lindstrm and Kleen-Tex | Started in Finland, now a strategic Europe-wide collaboration. |

| More recycled content, same performance | Core mats increased from 50% to 75% recycled content without compromising durability or quality. |

| How they got there | Close supply-chain collaboration and rigorous testing (incl. with RadiciGroup) plus Lindström technical feedback. |

| What’s next | A Life Cycle Assessment (LCA) programme in 2025–2026 and continued work toward refurbishment and more circular mat solutions. |

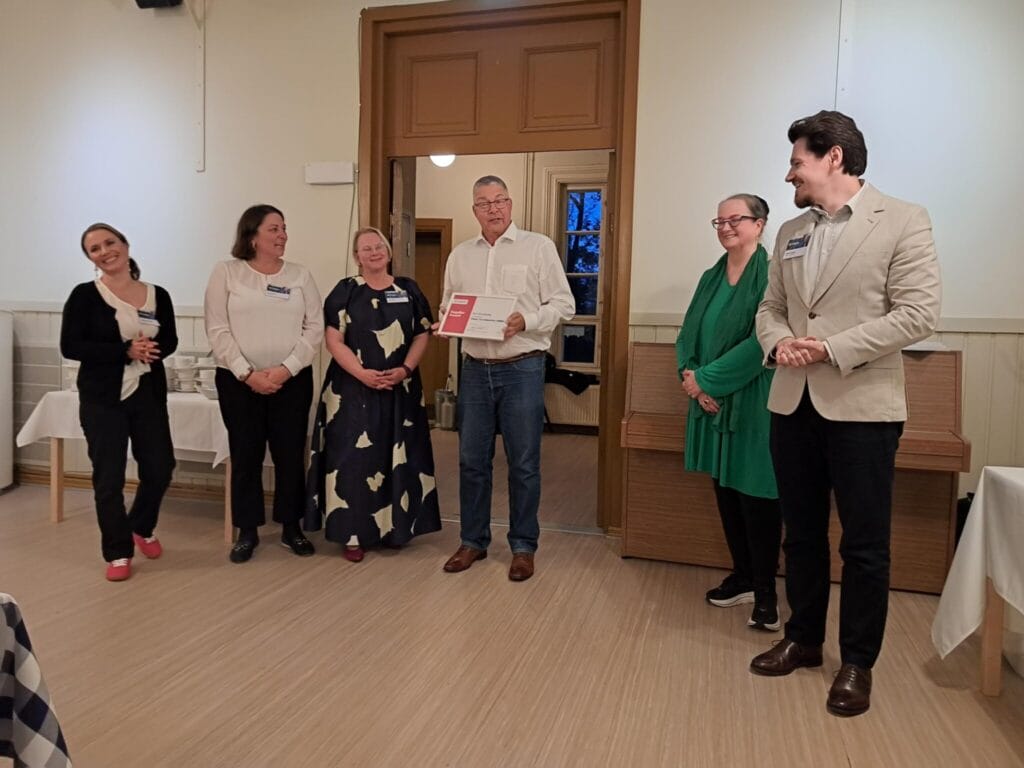

Kleen-Tex is one of Lindström’s most experienced partners for dust control mats. What started as a small-scale collaboration in Finland 30 years ago has grown into a strategic partnership across Europe. At our first Supplier Days, Kleen-Tex received the Supplier Award for Circularity in recognition for their work developing mats with a high share of recycled content, without compromising durability or quality.

We spoke with Lee Fox, Chief Operating Officer, and Marek Dulęba, Operations Director at Kleen-Tex, to hear how this transformation came to life, and what comes next.

Sustainability starts with responsibility

As a global manufacturer, Kleen-Tex knew they needed to do more to reduce their environmental impact.

“Our products are created from ingredients that deplete global resources and use greenhouse gas energy in production. We knew we had to reduce our carbon footprint, minimise waste, and conserve resources,” says Lee Fox.

In 2021, they made a clear commitment: from that point on, all new products developed and launched in Europe would contain recycled materials. By 2022, this had become standard practice.

The shift was not only driven from within. Customers were also pushing for more sustainable solutions. As Lee explains:

Working with forward-thinking customers like Lindström helped us increase recycled content in our core products from 50% to 75%.

Lee Fox, Chief Operating Officer at Kleen-Tex.

Performance can’t be sacrificed

Improving sustainability while keeping product quality was no easy task. Kleen-Tex faced several technical challenges, including polymer degradation, contamination, and maintaining core features like colour consistency, absorption, and mechanical strength.

We’re committed to ensuring that improvements in one area never come at the expense of the performance our customers expect.

Marek Dulęba, Manufacturing Director at Kleen-Tex.

The solution required close collaboration with their yarn supplier, RadiciGroup, and intensive product testing. The team validated that recycled nylon, made from production scrap, could meet the same performance standards as virgin materials.

“We confirmed through rigorous testing that we could preserve key characteristics like resistance, elasticity, dyeability, and absorption.”

Regular feedback from Lindström’s technical team helped refine the product before launch.

Collaboration across the supply chain

For Kleen-Tex, sustainability isn’t just about their own operations it spans the entire supply chain.

We work proactively with our sub-suppliers to validate their environmental credentials. This is through certifications, sustainability reports, audits, and company policies.

Marek Dulęba, Manufacturing Director at Kleen-Tex.

They’re also realistic: full traceability remains an industry-wide challenge. But Kleen-Tex is committed to continuously improving supply chain visibility and data quality together with their partners.

Measuring and improving impact

Kleen-Tex tracks environmental performance through regulatory reporting, customer frameworks like Lindström’s Annual Emissions Survey, and on-going supplier data monitoring. Now, the team is taking things a step further.

“We’re launching a full Life Cycle Assessment (LCA) programme in 2025–2026. The first product to be assessed will be our Iron-Horse XL Eco mat,” says Marek.

The LCA will provide a clear benchmark for environmental impact across the full product lifecycle, and guide future development.

A partnership built over decades

Kleen-Tex’s relationship with Lindström spans for decades.

“We started as a low-volume supplier working with Finland. Today, we’re the main supplier of high-quality dust control matting across Europe and beyond,” says Lee.

He highlights that despite the size difference, the two companies have often followed similar paths, especially around sustainability and circularity.

“That connection has been instrumental in helping both sides continuously improve. We’re proud to be a Lindström partner and look forward to reaching our goals together.”

Looking ahead: from recycled to circular

For Kleen-Tex, the shift to 75% recycled content is just a step. The focus now is on designing sustainability into every product from the beginning.

“Sustainability and circularity are embedded as design principles in our business,” Lee explains. “We’re already working toward the next generation of materials and processes.”

They’re standardising sustainability across global sites in Poland, Thailand, Japan, and South Africa, while allowing space for local innovation. A global team of specialists is testing new materials, without compromising on durability.

Kleen-Tex is also developing a mat refurbishment process to extend product life and reduce resource use. Fully circular matting, where used mats become new ones, is not yet commercially viable, but the team continues to explore it.

“This is just one step. We’re committed to investigating all possibilities,” says Lee.