Sustainable solutions with DingYuan Textile Technology

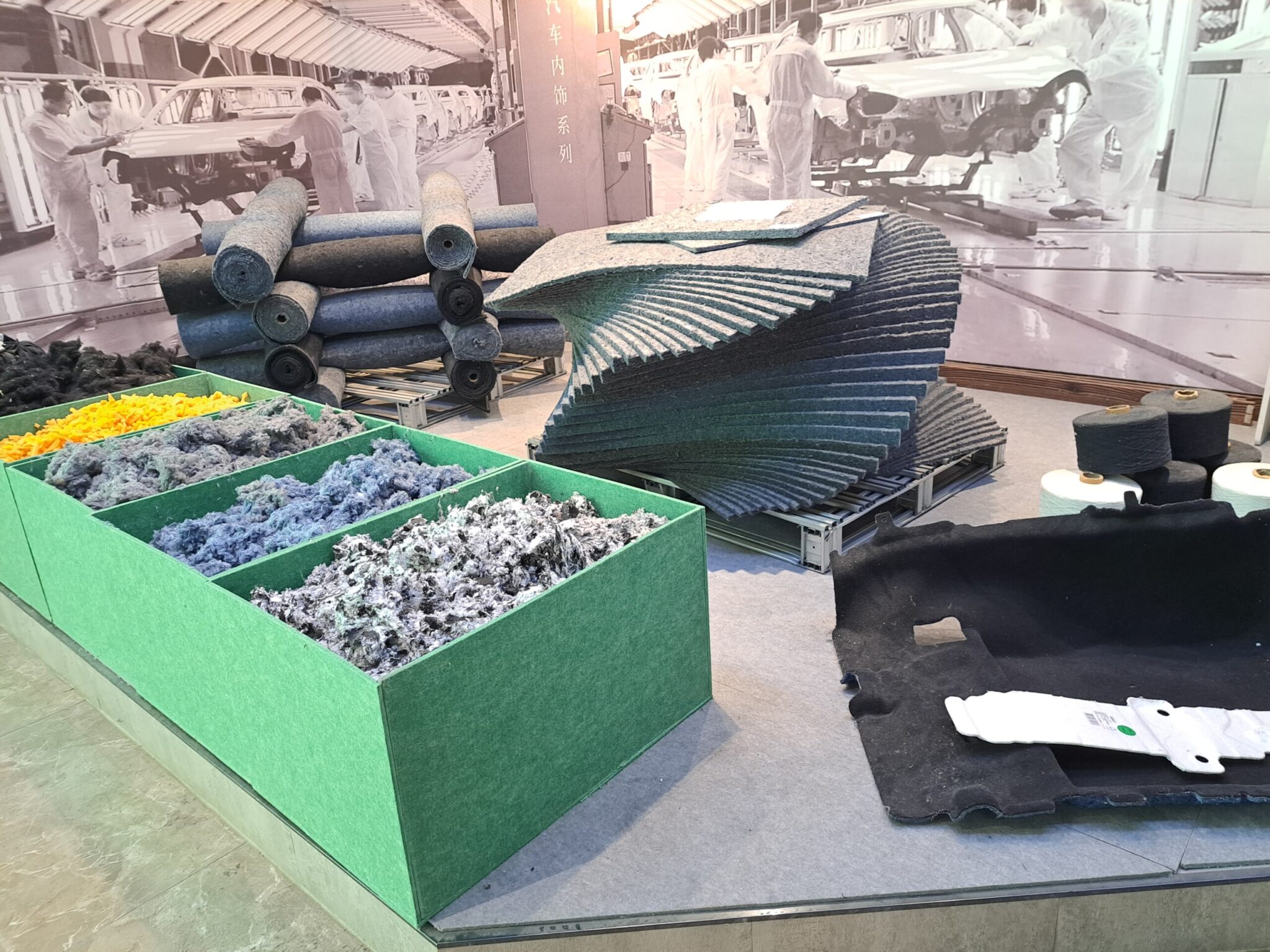

A large factory in the city of Hangzhou hides one of the pioneering textile recycling companies in China, DingYuan Textile Technology. Founded in 2015, it spreads across 30,000 square metres and recycles 60,000 tons of textiles annually. It collaborates with leading global brands recycling textile waste and developing new products from recycled waste.

We are welcomed by Pierre Lu, the managing director of DingYuan Textile Technology. Pierre has been working for the company since its founding and takes us on a tour of the factory. On the wall of the factory hangs various certificates. Among others, the Certificate of GRS, the Global Recycling Standard that tracks and verifies the content of recycled material in final products.

Choices guided by sustainability

The recycling partner picks up our end-of-life textiles from our service centres in Suzhou, Shanghai and Jiaxing. They sort them, remove all the buttons and zippers, cut the clothes into pieces and produce recycled fibre. The short, non-spinnable fibre is used for building-, acoustic- and packaging material. The long, spinnable fibres are weaved as fabric and used for clothing and home decoration.

”Our choices are guided by sustainability. We use mechanical recycling as it consumes less water and energy than chemical recycling. We don’t add any chemicals or recolour our end products, which saves energy,” Pierre Lu explains.

The latest report from autumn 2023 shows that over 11,000 kg of our textile waste was transported to the facility for recycling during the year. Almost 90% of the waste was recycled mainly as storage boxes. The unrecyclable material included waste shoes and extremely soiled garments. They were disposed of as fuel rods for biomass fuel. This is an essential raw material for energy companies. They are only allowed to take 75% of their energy from coal.

Our collaboration may expand in the future. Pierre Lu shares that they are planning to open a new branch in Wuhan this year. Aditionally, the company explores the possibility of expanding their business to Guangzhou. Both are locations where Lindström operates.

A quest for closed-loop solutions

Adam Liu, our purchase manager, responsible for the partnership at Lindström shares: “We have been exploring closed-loop textile recycling together. For example, by using recycled fibres from our textile waste in our summer and winter garments. The third round of winter garments will be ready soon and we are eagerly awaiting a chance to test them.”

There are still several challenges, including the durability of the materials that are expected to be at the level of virgin materials and overall market acceptance in China. Second-hand clothing and recycled materials in garments are not widely accepted in China. People are skeptical about the level of hygiene and the quality of the products.

“We need a change of mindset in China,” notes Pierre Lu, who continues: “Products that are not garments are more accepted if the quality is the same. The Chinese also expect recycled materials to cost less, although the case is often just the opposite – for example, recycled polyester costs 20% more than virgin material.”

Pierre Lu explains that DingYuan Textile Technology also collaborates with schools and students to educate them on the benefits of recycling: “The best way to showcase our expertise is to do something together with students from their old garments.”

He also believes that big global companies play a big role in development: “When pioneering global fashion and textile companies lead the way and use recycled materials in their products, they may impact the opinion of the public. That is why we value this collaboration with Lindström and see great potential in educating the market about the benefits of recycled materials together with Lindström and its customers.”