What is microbial control in ISO Class 7 cleanroom garments?

In industries where sterility is critical, such as pharmaceuticals and electronics, contamination can have catastrophic consequences. Consider this: a single particle of dust or microbial contamination in pharmaceutical production can lead to entire batches being rejected, costing companies millions and putting safety at serious risk. This underscores the importance of cleanroom garments in maintaining sterile environments. This article explores the design, application, and management of ISO Class 7 cleanroom clothing, focusing on its role in microbial control and the challenges in ensuring its effectiveness.

How ISO Class 7 cleanroom gowns are designed

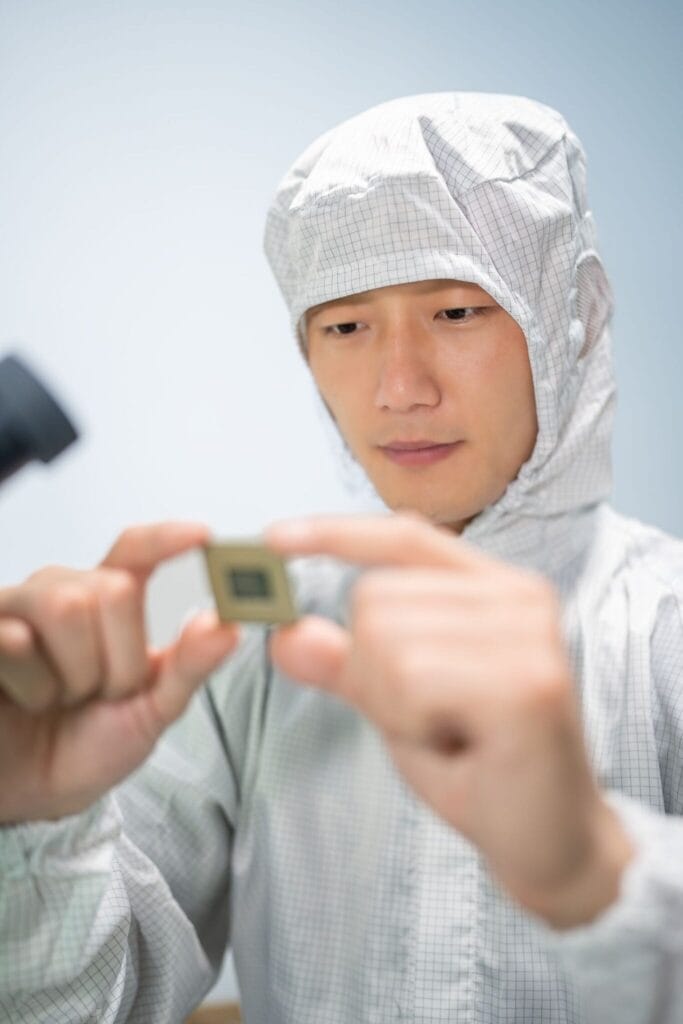

ISO Class 7 cleanroom garments are carefully designed to reduce contamination risks. These garments are made from non-linting materials, meaning the fabrics are designed not to shed fibres that could contaminate the environment. Advanced textiles also incorporate anti-static properties to prevent particle accumulation and electrostatic discharge, both of which can compromise cleanroom integrity.

The garment design includes seamless stitching and features such as integrated hoods, face masks, and boots, ensuring comprehensive coverage. Such designs act as effective barriers, reducing contamination from skin, hair, or other particulates. By using advanced manufacturing techniques, cleanroom garments upholds strict ISO standards for cleanliness and safety.

Key Terms Simplified:

- Non-linting: Fabrics that do not release fibres into the air, reducing contamination risks.

- Particle shedding: The release of microscopic particles from clothing, which can compromise cleanroom sterility.

Practical applications of microbial control in cleanroom clothing

Cleanroom garments are essential in industries such as pharmaceuticals and electronics, where contamination control is critical. In pharmaceutical manufacturing, even minimal contamination can compromise drug safety, leading to costly recalls and risking patient health. Proper gowning practices ensure that personnel do not introduce contaminants during production.

Similarly, in biotechnology, sterile environments are essential for preserving the integrity of biological samples. Electronics manufacturing requires stringent cleanliness to prevent defects in components like semiconductors. Across these industries, cleanroom garments protect products and personnel from hazardous substances.

Challenges in maintaining microbial control in cleanroom clothing

Despite their sophisticated design, cleanroom garments face several challenges:

- Improper Use: Incorrect donning and doffing procedures can introduce contaminants. Businesses can mitigate this through regular staff training and adherence to strict gowning protocols.

- Laundering Inefficiencies: Poor cleaning practices can leave residues that compromise garment sterility. Partnering with a specialized service provider like Lindström ensures laundering meets ISO 14644 and EN 14065 standards, with advanced washing techniques that maintain garment integrity.

- Material Degradation: Repeated laundering and sterilization can degrade garment effectiveness over time. Lindström’s RFID-enabled tracking system monitors garment life cycles, ensuring timely replacement to maintain optimal performance.

By addressing these challenges proactively with the right practices and partnerships, businesses can ensure their cleanroom operations remain secure and compliant.

Comparing ISO Class 7 cleanroom garment options

When choosing cleanroom garments for ISO Class 7 environments, companies often weigh the benefits of single-use versus reusable garments:

- Single-use Garments:

- Benefits: Eliminates contamination risks from laundering.

- Drawbacks: Higher environmental impact and long-term costs.

- Reusable Garments:

- Benefits: Cost-effective over time and aligns with sustainability goals. Lindström’s garments are designed for durability and undergo rigorous testing to ensure compliance with microbial control standards.

- Drawbacks: Requires specialised laundering to maintain sterility. However, a reliable service partner can support you in this challenge.

A partner like Lindström helps you reduce the environmental impact of reusable cleanroom garments, contributing to sustainable business practices while ensuring high-quality performance.

The importance of effective cleanroom clothing

Effective microbial control through cleanroom clothing is essential for maintaining sterile environments and meeting regulatory standards. Lindström’s certified laundering processes, coupled with RFID tracking systems, ensure consistent compliance and reduce contamination risks. By investing in high-quality garments and reliable upkeep, companies can protect their products, processes, and reputations.

For businesses seeking reliable and sustainable cleanroom solutions, Lindström offers end-to-end services tailored to ISO Class 7 requirements. Partnering with industry experts ensures that cleanroom operations not only meet but exceed regulatory expectations, fostering safety, efficiency, and sustainability.