ESD Shoes vs. Regular Safety Shoes: What’s the Difference in 2026?

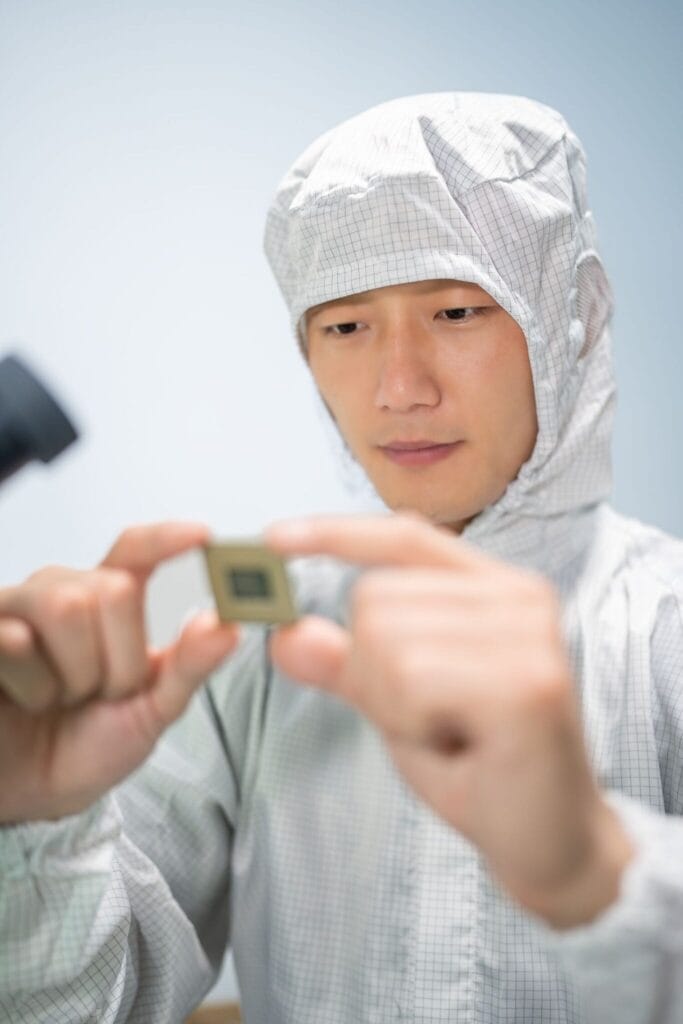

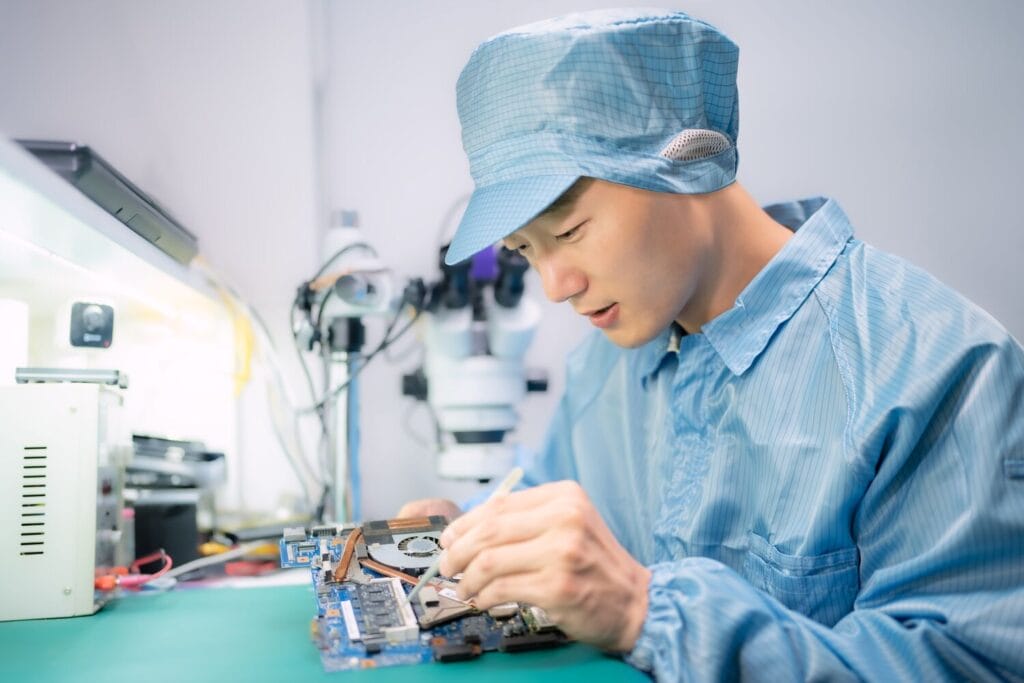

Electrostatic discharge (ESD) is a hidden but serious risk in many industrial, laboratory, and cleanroom environments. Even a minor static spark—imperceptible to humans—can irreversibly damage electronic components, disrupt precision manufacturing processes, or ignite flammable substances. For organizations operating in electronics manufacturing, pharmaceuticals, biotechnology, aerospace, or hazardous-material handling, controlling static electricity is not optional; it is a fundamental safety and quality requirement.

One of the most effective and often underestimated controls in an ESD protection system is ESD safety footwear. Properly designed ESD shoes play a critical role in safely dissipating static charges from the human body to the grounded floor, preventing uncontrolled discharge events that can compromise both safety and product integrity.

What Are ESD Safety Shoes and How Do They Work?

ESD shoes are engineered with conductive or dissipative materials embedded into their structure—most commonly within the sole. These materials may include carbon-infused rubber, conductive PVC compounds, or metallic fibers that form a controlled electrical pathway.

Controlled Resistance for Maximum Safety:

Unlike standard anti-static footwear, ESD shoes are designed to maintain a specific resistance range, typically between 0.1 MΩ and 100 MΩ.

This resistance window is critical:

- Resistance that is too low may expose the wearer to electrical shock

- Resistance that is too high can allow static charge buildup and spark generation

By maintaining this balance, ESD footwear enables controlled dissipation of electrostatic charges, protecting electronic assemblies, semiconductor manufacturing lines, cleanroom equipment, and environments with flammable substances.

Footwear Design Options and Material Choices:

To support different operational demands, ESD safety shoe is available in a wide range of configurations:

Shoe Design:

- Low-ankle styles for flexibility and comfort in controlled indoor environments.

- Mid-ankle designs for enhanced support and stability in demanding production areas.

Sole Technologies:

- Conductive rubber soles for long-term durability and consistent electrical performance.

- PVC-based soles offering lightweight comfort and ease of maintenance.

Upper Materials:

- Leather uppers for robustness and extended service life.

- Synthetic or microfiber materials for cleanroom compatibility and easier sanitation.

Optional ESD shoe covers provide an additional layer of protection, particularly in high-risk or ultra-sensitive environments where contamination control and redundancy are essential.

Why a Managed Rental Model Improves ESD Shoe Compliance?

Managing ESD shoes in-house can be complex. Shoes require routine cleaning, resistance testing, documentation, repair, and replacement—often across multiple shifts and locations. A professionally managed rental model eliminates these challenges by offering full lifecycle control.

A B2B rental solution, such as the one offered by Lindström, ensures footwear is hygienically cleaned, regularly tested, replaced when out of specification, and delivered on a schedule aligned with operational requirements—without burdening internal teams.

Benefits of a Rental-Based Approach:

- Workforce-aligned shoe allocation based on roles and shifts.

- Scheduled replacement to prevent degraded footwear from entering production areas.

- Industrial cleaning and disinfection processes.

- Routine electrical resistance testing in certified facilities.

- Digital compliance records to support audits and certifications.

Technological Advancements in Modern ESD Footwear:

ESD footwear has evolved significantly, integrating advanced materials and monitoring capabilities.

Advanced Dissipative Materials:

Next-generation soles incorporate high-performance conductive compounds—such as carbon nanotube structures—that dissipate static charges faster than conventional anti-static materials, while maintaining durability and wearer comfort.

Smart Monitoring Capabilities:

Some ESD footwear solutions now include embedded sensors that continuously monitor resistance values. When resistance moves outside the acceptable tolerance range, the footwear can be flagged for replacement before it becomes a safety risk.

International Standards and Compliance Requirements:

Professional ESD shoes must comply with internationally recognized standards, including:

- DIN EN 61340-5-1 for electrostatic protection of electronic devices.

- EN ISO 20347:2022 (ESD-S1) for occupational footwear.

These standards typically require footwear resistance to remain within 10⁴–10⁶ ohms, ensuring safe static discharge without compromising electrical safety. Full traceability and documentation are essential to demonstrate ongoing compliance during audits.

Rental vs. Purchase: Cost and Risk Considerations

Purchased footwear often results in inconsistent inspections, unclear replacement cycles, and higher risk of non-compliant shoes remaining in use. In contrast, rental models convert footwear management from a capital expense to a predictable operational cost, bundling cleaning, testing, replacement, and documentation into a single service.

This approach reduces administrative overhead, improves budgeting accuracy, and significantly lowers the risk of ESD-related incidents.

Industry Applications for ESD Safety Shoe Services:

ESD shoes rental programs are particularly valuable in:

- Electronics and PCB assembly.

- Semiconductor manufacturing.

- Pharmaceutical and biotech cleanrooms.

- Aerospace and precision engineering.

- Chemical processing and hazardous-material handling.

- Battery and EV component production.

In these environments, even a single uncontrolled electrostatic discharge can result in product failure, safety incidents, or costly downtime.

Future Developments in ESD Footwear and Compliance:

Looking ahead, innovation in ESD footwear is expected to include ultra-light composite toe caps, app-connected resistance monitoring, and sustainable materials designed for circular lifecycle models.

Regulatory bodies are also moving toward digital compliance and traceability requirements, where every piece of protective equipment must have a documented performance history. Providers such as Lindström are adapting their digital platforms to support these evolving demands and ensure long-term regulatory readiness.

Conclusion:

ESD safety shoe is a critical component of any static control program in sensitive production and laboratory environments. A professionally managed rental model ensures consistent compliance, improved hygiene, and reduced operational risk—while allowing organizations to focus on productivity and quality.

Evaluate modern ESD shoes solutions today to strengthen workplace safety, protect valuable products, and stay ahead of evolving compliance standards.

Frequently Asked Questions:

What are the primary benefits of renting ESD shoes instead of purchasing them?

Rental eliminates capital expenditure, ensures continuous compliance through scheduled maintenance and testing, and includes hygienic cleaning and replacement as part of a predictable service fee.

How does Lindström ensure hygiene and performance in its rental program?

Each pair undergoes professional laundering, disinfection and electrical resistance testing in accredited labs. Non-compliant shoes are immediately withdrawn and replaced to guarantee your safety standards.

What resistance levels distinguish ESD shoes from anti-static shoes?

ESD shoes operate between 0.1 MΩ and 100 MΩ for rapid static dissipation. Anti-static shoes typically range from 0.1 MΩ to 1,000 MΩ, offering slower charge release more suited to general workplace environments.

When should a business choose ESD footwear over standard safety shoes?

If your operations involve sensitive electronics, flammable solvents, or explosive materials, ESD safety shoes are essential to prevent static-induced damage or ignition. For environments requiring additional layers of static management, incorporating an esd shoe cover can help maintain compliance and provide enhanced protection. Standard safety shoes focus on impact and puncture protection but do not actively manage static charges.