What Are ESD Shoe Covers and Why Are They Essential in Static-Sensitive Areas?

In industries where sensitive electronics, precision components, and controlled environments are standard, electrostatic discharge (ESD) represents a constant and often invisible threat. Even minor static buildup on personnel can result in catastrophic damage to electronic assemblies, semiconductor wafers, or high-value medical devices.

ESD shoe covers are a critical part of a comprehensive electrostatic control strategy. They provide a controlled grounding path that safely dissipates static charges generated by human movement, footwear friction, or environmental conditions. When combined with grounded flooring systems, ESD mats, wrist straps, and ESD garments, shoe covers help maintain stable, compliant, and contamination-controlled production environments.

A professionally managed rental solution for ESD shoe covers ensures consistent protection, regulatory compliance, and operational efficiency without the burden of purchasing, storing, or disposing of consumables.

Understanding ESD Shoe Covers:

What Are ESD Shoe Covers?

ESD shoe covers are disposable, or limited-use protective overshoes designed to prevent electrostatic charge accumulation on personnel. They are worn over standard footwear, ESD shoes, or ESD safety shoes to ensure continuous grounding as employees move across conductive or dissipative flooring.

Their primary functions include:

- Dissipating static electricity safely.

- Protecting sensitive electronic components.

- Supporting cleanroom contamination control.

- Enhancing workplace safety and regulatory compliance.

Composition, Design, and Variants:

Modern ESD shoe covers are engineered for both electrical performance and environmental control.

Typical construction includes:

- 100% spun-bond polypropylene for durability and low particle shedding.

- Integrated conductive carbon strips or ribbons along the sole to create a continuous discharge path.

- Latex-free, anti-allergenic materials suitable for sensitive personnel.

- Slip-resistant or skid-resistant soles to improve traction on smooth or wet floors.

Available variants may include:

- Multiple lengths (typically 15–18 inches).

- Color options for zone control or compliance identification.

- Reinforced designs for high-traffic industrial use.

- Dissipative rubber sole models for enhanced grounding.

These covers are compatible with most industrial footwear, including ESD shoes, ESD safety shoes, and ESD cleanroom shoes, making them suitable for a wide range of applications.

How ESD Shoe Covers Work?

ESD shoe covers create a controlled and continuous discharge path between the wearer and a grounded surface. The process typically involves:

- Contact between the conductive strip and the wearer’s shoe, sock, or skin.

- Transmission of static charges through the conductive element.

- Dissipation of electricity into grounded flooring, ESD mats, or conductive tiles.

This mechanism prevents voltage buildup on personnel, eliminating sudden electrostatic discharges that could damage components, disrupt automation, or compromise product quality.

Types of ESD Shoe Covers:

Different environments require different ESD shoe cover solutions. Common types include:

1. Disposable ESD Shoe Covers

- Made from non-woven polypropylene or CPE.

- Integrated conductive strip or sole.

- Ideal for visitors, temporary workers, or short tasks.

2. Reusable ESD Shoe Covers:

- Designed for repeated use and laundering.

- More durable materials with long-term cost efficiency.

- Suitable for regular personnel in controlled environments.

3. ESD Shoe Covers with Skid-Resistant Soles:

- Feature textured or rubberized bottoms.

- Reduce slip hazards in industrial settings.

4. Cleanroom-Compatible ESD Shoe Covers:

- Designed for ISO 5–8 cleanroom environments.

- Control both static discharge and particulate contamination.

Typical Technical Features of ESD Shoe Covers:

| Feature | Description |

|---|---|

| Material | Non-woven polypropylene / CPE |

| Conductive element | Carbon or conductive ribbon |

| Electrical function | Dissipative grounding path |

| Sole type | Conductive or skid-resistant |

| Compatibility | ESD flooring systems |

| Cleanroom class | ISO 5–8 (depending on model) |

The Importance of ESD Protection in Sensitive Areas:

Preventing Component Damage:

Electrostatic discharges as low as 10–100 volts—far below what humans can feel—can permanently damage microelectronic circuits or weaken semiconductor junctions.

Without adequate ESD controls, organizations face risks such as:

- Latent defects that appear after shipment.

- Costly rework, scrap, or recalls.

- Production downtime and equipment failures.

- Loss of customer trust and brand reputation.

ESD shoe covers play a key role in stabilizing the electrostatic environment throughout production and handling processes.

Safety and Regulatory Compliance:

In certain environments, ESD events can ignite flammable vapors, interfere with medical devices, or disrupt sensitive instruments.

Proper use of ESD shoe covers supports compliance with major standards such as:

- ANSI/ESD S20.20

- IEC 61340-5-1

- EN 61000-4-2

Documented ESD control programs also simplify audits, inspections, and customer validations.

Top Industries That Require ESD Shoe Covers:

ESD shoe covers are essential across industries where static electricity, contamination, or precision risks can compromise safety, quality, or compliance.

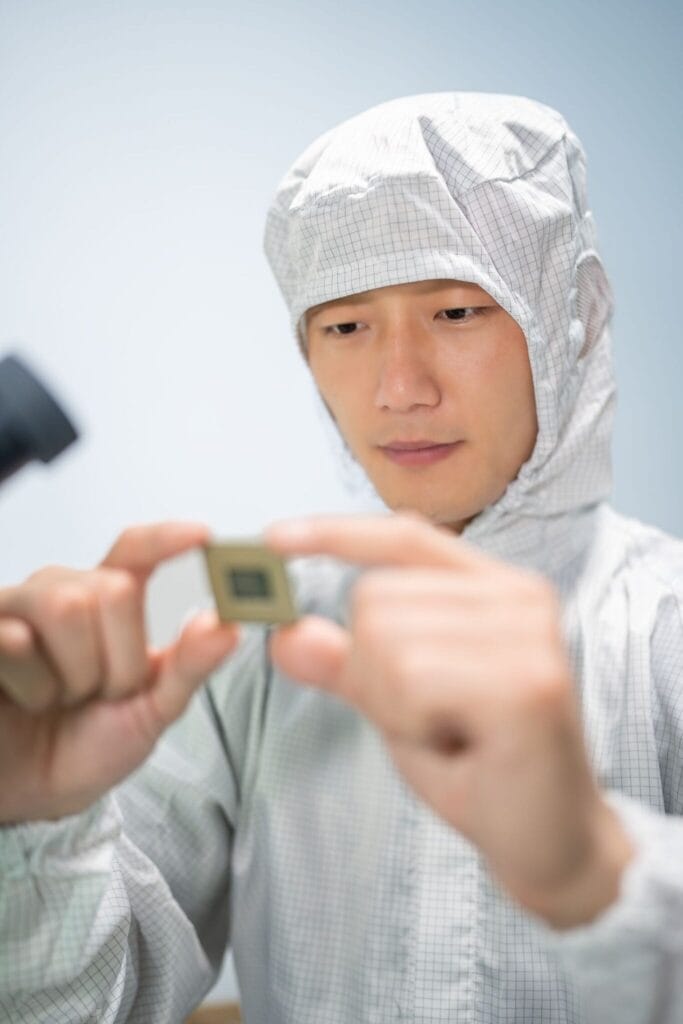

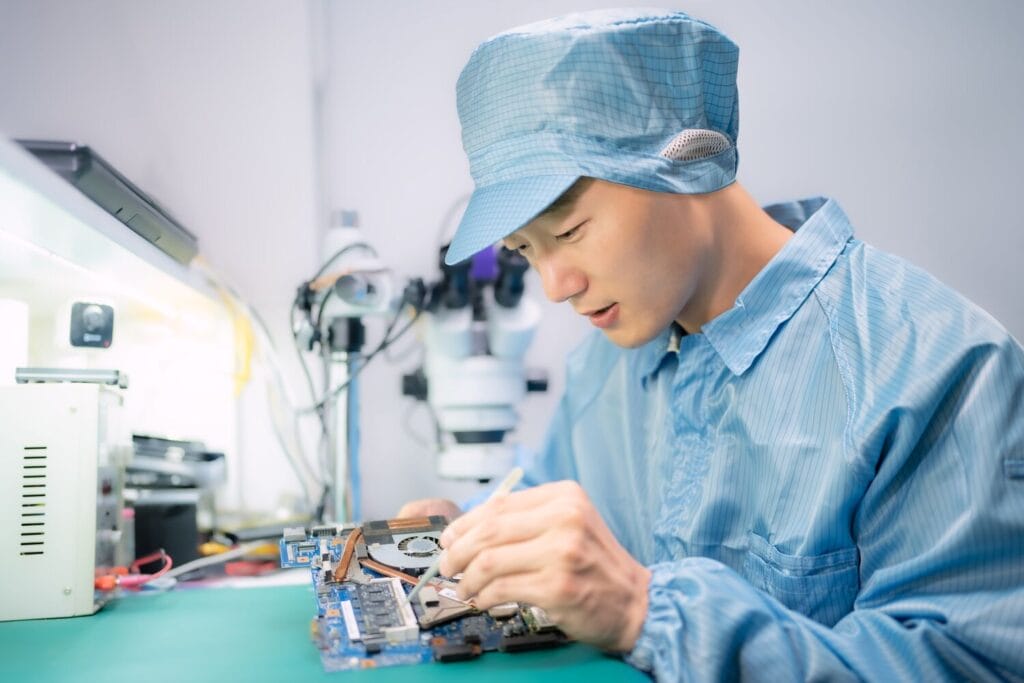

Electronics and Semiconductor Manufacturing:

This sector faces the highest ESD risk. Integrated circuits, PCBs, and semiconductor wafers can be destroyed by minimal voltage. Shoe covers help maintain continuous grounding for operators working in SMT lines, wafer fabs, and test environments.

Aerospace and Defense:

Avionics and mission-critical electronics demand extreme reliability. Latent ESD damage can lead to failures long after deployment, making strict ESD footwear controls essential.

Pharmaceutical and Medical Device Manufacturing:

Cleanrooms producing diagnostics, implantable electronics, or sterile products require both contamination control and electrostatic protection. Shoe covers address both risks simultaneously.

Automotive and Electric Vehicle Manufacturing:

Modern vehicles rely heavily on ECUs, sensors, and battery systems. ESD shoe covers reduce static-related failures during assembly, testing, and maintenance.

Precision Engineering, Optics, and Research:

Laboratories and R&D facilities working with lasers, optics, nanotechnology, and advanced materials depend on stable electrostatic conditions to ensure accuracy and repeatability.

Data Centers and IT Hardware Assembly:

Server manufacturing and hardware installation environments benefit from ESD shoe covers when handling memory modules, processors, and storage devices.

ESD Shoe Covers vs. Regular Shoe Covers:

| Feature | ESD Shoe Covers | Regular Shoe Covers |

|---|---|---|

| Static protection | Yes | No |

| Conductive grounding | Yes | No |

| Cleanroom compatibility | Yes (selected types) | Limited |

| Use in ESD areas | Mandatory | Not recommended |

How to Choose the Right ESD Shoe Covers for Your Workplace?

Selecting the correct ESD shoe covers requires aligning electrostatic protection needs with operational conditions.

- Required Level of ESD Control: Assess whether your environment involves highly sensitive electronics, general assembly, or visitor access to ESD-protected areas.

- Flooring Compatibility: Ensure the shoe covers are designed to work effectively with your existing conductive or dissipative flooring systems.

- Cleanroom Classification: Verify ISO cleanroom compatibility (ISO 5–8) where contamination control is critical.

- Fit and Comfort: Poorly fitting covers can slip, tear, or lose grounding contact. Choose sizes and elastic designs that fit securely over footwear.

- Slip Resistance and Worker Safety: In areas with polished or wet floors, skid-resistant soles are essential to reduce accident risks.

- Logistics and Usage Frequency: High-traffic environments benefit from managed supply or rental models that ensure consistent replacement and compliance.

Common Mistakes When Using ESD Shoe Covers and How to Avoid Them:

- Using Shoe Covers Without Grounded Flooring: Without grounding, static charges cannot dissipate. Always pair shoe covers with conductive flooring or ESD mats.

- Wearing Covers Over Incompatible Footwear: Insulating soles or poor fit can break the discharge path. Ensure proper contact between the conductive strip and the wearer.

- Reusing Disposable Covers Too Long: Worn covers may lose conductivity or shed particles. Replace them according to usage intensity and compliance guidelines.

- Ignoring Visible Damage: Tears, worn soles, or damaged conductive strips compromise effectiveness. Inspect covers before use.

- Relying on Shoe Covers Alone: ESD control requires a system approach. Shoe covers should complement wrist straps, garments, grounding points, and training.

- Lack of Training: Improper use reduces effectiveness. Regular ESD awareness training and clear signage improve compliance.

Best Practices for Using ESD Shoe Covers:

- Ensure covers make direct contact with socks or skin via the conductive strip.

- Combine with ESD flooring and grounding systems.

- Train employees and visitors on correct usage.

- Inspect covers regularly for wear or damage.

- Replace disposable covers after each use.

Rental-Based ESD Shoe Cover Programs:

A rental-based service model simplifies ESD management by ensuring consistent quality and compliance. Benefits include:

- Scheduled deliveries aligned with production shifts.

- Regular replacement and controlled disposal.

- On-site audits and documentation.

- Predictable costs and simplified reporting.

This approach allows organizations to focus on production rather than inventory or waste management. Lindström offers such a managed rental solution designed for B2B manufacturing and cleanroom environments.

Conclusion:

ESD shoe covers are a foundational element of any effective electrostatic control program. By ensuring continuous grounding, supporting regulatory compliance, and protecting high-value assets, they help organizations maintain productivity, safety, and product quality.

A professionally managed rental model further enhances reliability and operational efficiency. Lindström supports organizations with compliant, scalable solutions that protect sensitive environments from electrostatic risks.

Frequently Asked Questions:

What materials are ESD shoe covers made from?

Spun-bond polypropylene with integrated conductive carbon elements for static dissipation and particle control.

How are ESD shoe covers different from ESD shoes?

Shoe covers are worn over existing footwear, while ESD shoes have built-in conductive properties.

Are ESD shoe covers suitable for ISO cleanrooms?

Yes, many models are designed for ISO 5–8 cleanroom environments.

Can ESD shoe covers be worn over safety shoes?

Yes, they fit over most industrial and ESD safety footwear.

How often should ESD shoe covers be replaced?

Replacement depends on usage, environment, and compliance requirements.

Do ESD shoe covers work without conductive flooring?

They require grounded flooring or mats to function effectively.

Are ESD shoe covers reusable?

Most are disposable or limited use to ensure hygiene and performance.

Do ESD shoe covers reduce slip hazards?

Many designs include slip-resistant soles for improved safety.

Do ESD shoe covers help with audits?

Yes, they support documented ESD control measures for regulatory compliance.

Are ESD shoe covers latex-free?

Most modern ESD shoe covers are latex-free and allergy-safe.