Factors to Consider When Purchasing an Antistatic Coat: A Comprehensive Guide

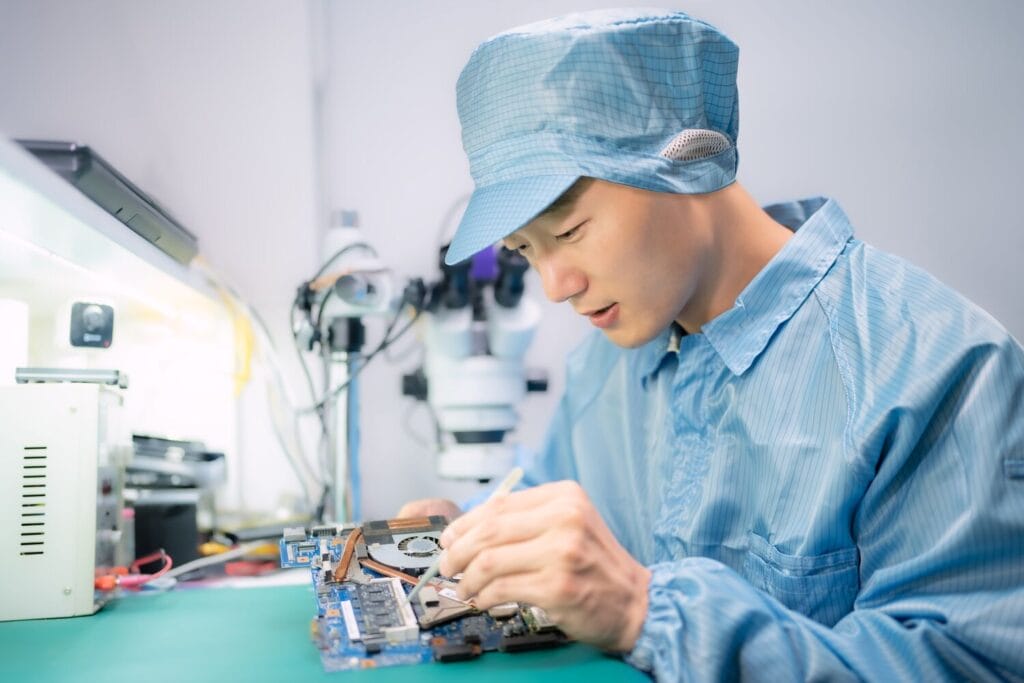

Choosing the right workwear style is crucial in diverse industries, but purchasing an antistatic coat is especially important for workplaces dealing with electronics and other sensitive equipment. Understanding the benefits an antistatic coat provides can significantly enhance the security and efficiency of your business operations. This blog post aims to provide businesses with a clear guide on what to consider when purchasing an antistatic garment, ensuring worker safety and product protection.

Understanding Antistatic Garments

Electrostatic discharge (ESD) has the potential to ruin sensitive electronic equipment. That’s where the role of an antistatic coat becomes prominent. Constructed with conductive materials, these garments reduce the risk of an electric shock that might harm electronic components or personnel. They form a fundamental part of an Electrostatic Discharge Protected Area (EPA), ensuring all conductive and dissipative materials in the vicinity are grounded.

Key Considerations

- Material and Conductivity: One key factor to consider is the choice of material. An ideal antistatic coat is made from materials that slowly conduct static charges away, preventing the accumulation of static electricity on the user’s body. It’s also essential that the incorporated material is durable enough to withstand numerous daily strains and stressors.

- Groundability: A well-designed antistatic garment can easily and reliably connect the user to the ground. This allows for the dispersion of any built-up electrostatic charge, helping to prevent a potentially damaging discharge. Remember, the efficacy of an antistatic coat certainly lies in its level of groundability.

- Suitability for your Industry: What suits the medical industry may not suit the electronic industry. Therefore, consider the specific requirements of your industry when selecting an antistatic garment. For example, any materials that will come into contact with conductive areas of ESD-sensitive electronics in the electronics industry should be made of dissipative material.

Maintenance and Durability

Maintenance is another vital aspect when investing in antistatic garments. Regular detergents can destroy the garment’s ESD property. Thus, understanding the washing directions is crucial, and any staff cleaning these coats should be appropriately instructed on the cleaning process.

Moreover, the strength and durability of the fabric should be considered. The longevity of an antistatic garment depends on its ability to sustain its integrity even after repeated usage and washing.

One additional factor to consider is whether the coat’s production is eco-friendly. As businesses become more aware of their environmental responsibilities, ensuring the sustainability of your antistatic garment has never been more significant for maintaining your company’s eco-conscious reputation.

Lindstrom’s Antistatic Clothing Solutions

When considering what antistatic garment to integrate into your workplace, it’s worth exploring the solutions industry leaders like Lindstrom offer. Their commitment to serving the electronics manufacturing domain is evident in their ElectroPro collection.

This clothing range is meticulously designed to meet the unique demands of the electronics industry, aligning with the stringent EN IEC 61340-5-1 standards. Each piece of their attire retains ESD protective qualities even after 50 washes, assuring sustained protection and a longer lifecycle. Lindstrom’s service extends beyond providing antistatic garments; it’s an all-encompassing workwear management solution. Their rental service includes the garments, washing and maintenance, delivery, and even a unique RFID-tagging system that offers real transparency and control over your garment inventory. By aligning with their expertise, you ensure that your ESD workwear is effective, cost-efficient, and easy to manage, supporting your business’s productivity and employee satisfaction with apparel that adheres to strict industry standards.

Conclusion

Investing in the right antistatic coat can benefit your business in several ways, from improving workplace safety to protecting sensitive electronics and maintaining production efficiency. By considering material and conductivity, groundability, suitability, maintenance, and durability, you can make an informed decision that will benefit your workers and your bottom line.

Ensure that you understand every aspect of your antistatic garment’s functionality – it’s not just a piece of workwear; it’s a measure of safety and efficiency and delivers your sustainability goals.