ESD apron in India: a simple, front-line shield for your products

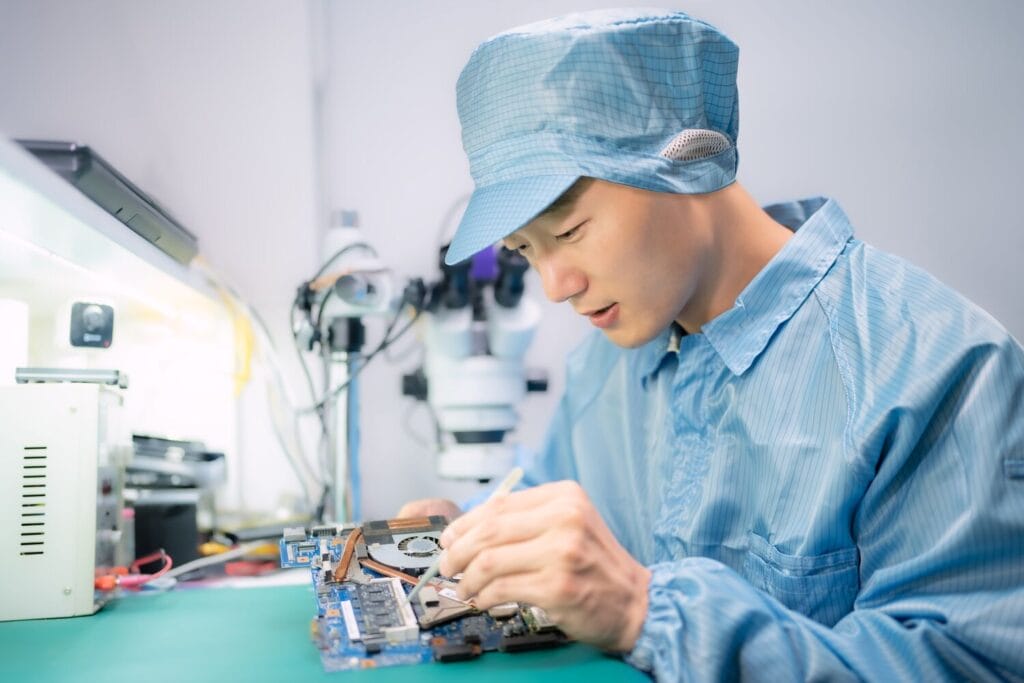

Every person who walks into your line brings two things you do not want near sensitive products. Static charge from their everyday clothes, and particles such as lint and skin flakes. If you work in electronics, diagnostics or pharma, both can quietly damage your output.

An ESD apron is a simple front-line shield between the operator’s clothing and your product. The right ESD apron controls static, covers dusty everyday fabrics, and supports your ESD and contamination control program at the same time. For many Indian sites, it is the easiest first step to better discipline on the line.

In this blog, we will explore what an ESD apron is, what can go wrong with the wrong apron, how to choose a suitable design for your cleanroom or lab in India, how to maintain these garments, and how Lindström India can support you with a managed apron and cleanroom esd garments service.

What is an ESD apron and how does it work?

An ESD apron is a protective garment worn over everyday clothing to control electrostatic discharge and particle shedding. It covers the front and sides of the body where most contact with sensitive products occurs.

How it works:

- Prevents sudden discharge from clothing or lint transfer onto products.

- Made from static-dissipative polyester with woven conductive fibers (e.g., carbon).

- These fibers create a controlled path for charge to move safely.

ESD apron vs antistatic apron:

You may see both “ESD apron” and “antistatic apron” in the market. The terms are often used loosely, but in practice:

- An antistatic apron is a general garment that reduces the chance of static build up.

- An ESD apron is a type of antistatic garment designed as part of a formal ESD control system for electronics or similar processes and is tested against standards such as IEC 61340-5-1 and IEC 61340-4-9 for garments.

From your point of view as an operation or EHS manager, the important question is simple. Does this apron have proven, tested ESD performance and low lint, or is it just “nice fabric”?

Part of a wider ESD garment system:

An esd lab apron or apron for assembly lines does not work alone. It is one part of a system that usually includes:

- ESD flooring and footwear

- Wrist straps or other grounding for seated work

- Other cleanroom esd garments such as coats, trousers and hoods where needed

Standards like IEC 61340-4-9 set out how to measure the electrical resistance of garments, including aprons. They explain how to test that the fabric and design really provide a controlled path for charge.

| Feature | Cotton Apron | Antistatic Apron | ESD Apron | Cleanroom ESD Apron |

|---|---|---|---|---|

| Static control | ❌ None | ⚠️ Basic | ✔️ Tested & controlled | ✔️ Controlled + low-lint |

| Lint | High | Medium | Low | Very Low |

| Standards | None | EN 1149 (sometimes) | IEC 61340-5-1, 4-9 | IEC 61340 + cleanroom specs |

| Suitable for electronics | ❌ | ⚠️ | ✔️ | ✔️✔️ |

| Suitable for diagnostics/pharma | ❌ | ⚠️ | ✔️ | ✔️✔️ |

What can go wrong with the wrong apron?

If teams use non-ESD cotton aprons or home-made solutions, the apron can quietly become a source of risk instead of protection.

Typical risks on electronics and assembly lines:

In Indian electronics plants and test labs, we often see:

- Micro-damage to PCBs: Everyday clothing under a cotton apron still charges up. When the person leans over a board, charge can jump to sensitive components. Many of these events never show up as a bang or spark, but they can cause latent failures.

- Nuisance failures in sensitive devices: Diagnostics devices, telecom modules and other electronics may pass final test. Later they fail in the field during warm-up or vibration because of earlier ESD stress near assembly or test benches.

- Noise in measurement and test equipment: In labs, static on clothing can disturb low-level measurements, leading to confusing test results and repeat work.

- False confidence: Operators feel “gowned up” in a normal cotton apron with an ESD logo printed somewhere, but no one has ever tested the garment or checked the fabric specification.

Problems in diagnostics and pharma environments

In diagnostics, biotech and pharma, the apron also has a contamination control role:

- Particles and fibers from clothing: Non-ESD cotton aprons do not control lint. Fibers from shirts and sarees can reach open samples, vials, or optical surfaces.

- Audit findings: Regulators and customer auditors increasingly ask how cleanroom garments, including aprons, are specified, tested and laundered, in line with standards like EU GMP Annex 1 for sterile manufacturing and general contamination control. Weak justification for apron use can trigger observations.

- Home-made apron policies: We sometimes see teams sewing their own “long coats” or aprons locally. These may look neat but usually have no documented fabric performance, no test data and no clear replacement rules.

Common red flags in Indian facilities:

Some warning signs that your current approach to aprons is weak:

- Mix of different colours, fabrics and lengths in the same area, with no clear reason

- No records of ESD or resistance testing for aprons

- Aprons washed at home or in general laundries with fabric softener

- No clear rule whether visitors should wear ESD aprons or not in sensitive areas

All of these increase the chance of static or particles reaching your product, often without any obvious visual clue.

How to choose the right ESD apron for your cleanroom?

Choosing an esd apron is not a fashion decision. It is a technical PPE choice that affects product quality and audits. Here is a practical buyer’s guide you can use with suppliers and internal stakeholders.

1. Check ESD performance and standards:

Start by asking for clear technical data:

- Fabric and apron should be suitable for ESD control in an EPA, tested in line with IEC 61340-5-1 or ANSI/ESD S20.20.

- For garments, ask specifically about IEC 61340-4-9 testing, which covers resistive characterization of static control garments such as coats and aprons.

- Make sure the apron is static dissipative, not fully insulating, and that resistance stays within the required range after multiple washes.

If a supplier cannot provide this information, treat the product as non-ESD.

2. Fabric technologies and low-lint properties:

The heart of an ESD apron is the fabric:

- Look for woven or knitted fabrics with continuous conductive fibers, such as carbon yarns in a grid or stripe pattern.

- For cleanroom esd garments, choose low-lint polyester fabrics designed to release very few particles.

- Check if the fabric also complies with antistatic clothing standards like EN 1149, especially if you use the same aprons in flammable atmospheres.

Ask for test reports and, ideally, sample swatches to check feel and opacity over your typical clothing.

3. Design features for protection and comfort:

A good esd lab apron or assembly apron protects without getting in the way:

- Length and coverage: Aprons should cover at least from shoulder to below the knee for most seated and standing work and wrap around the sides enough to protect against side contact with benches.

- Closure type: Press studs or snap buttons are often better than ties in ESD environments, as they give consistent closure and can be handled with gloves. Avoid large metal zips that might scratch products.

- Pockets: Keep pockets to a minimum in critical areas. Where needed, choose flat, closed pockets for pens or small tools, not open patch pockets that collect debris.

- Adjustability: Adjustable neck and waist straps help fit different body types, which is important in esd workwear for assembly lines with many operators.

- Identification: Consider simple colour coding or badges by zone or role so floor supervisors can see at a glance if someone is wearing the correct apron.

4. Comfort and mobility in Indian conditions:

If aprons are uncomfortable, people will “forget” them:

- Choose fabric weights that balance durability with breathability. Very heavy fabrics feel hot and stiff in Indian climates, especially for long shifts.

- Make sure the cut allows operators to sit, bend and reach without pulling tight at the shoulders.

- For cleanrooms, confirm that any mesh or ventilation panels are also ESD safe and low-lint, not just ordinary netting.

Short trials with real operators on your line are worth far more than a glossy brochure.

5. Fit with your cleanroom and ESD concept:

The esd apron should match the rest of your protection:

- In electronics EPAs, aprons usually work with ESD coats, footwear and wrist straps, not as a standalone solution.

- In diagnostics and pharma labs, they may be used over scrubs or basic cleanroom garments as an extra barrier when working near open product.

- Check that your SOPs clearly state where aprons are mandatory, optional or not allowed, so people do not drag them into the wrong zones.

6. Lifecycle cost and sustainability:

Finally, think beyond the purchase price:

- Consider how many washes the apron can handle while keeping ESD performance and appearance.

- Factor in the cost of washing, inspection, storage and disposal of worn-out garments.

- Reusable aprons managed in a rental or service model can often give better lifecycle cost than regular ad hoc buying and uncontrolled washing.

Gowning procedures: How to use ESD aprons without adding contamination

An ESD apron only helps if it is used correctly. Poor gowning practice can undo the benefits.

Storage:

- Store aprons hanging or folded in closed cupboards or dispensers near the entry to controlled areas.

- Separate clean and used aprons clearly, for example with colour tags or dedicated bins.

- Avoid leaving aprons on chair backs, equipment or over machine guards, where they can pick up dust and oil.

Donning:

- Put on base garments first, then the ESD apron as one of the final steps before entering the EPA or cleanroom.

- Make sure the apron fully covers the front of your clothing and is fastened properly.

- If you use ESD wrist straps, check that the apron does not interfere with the strap connection or lead.

Doffing:

- Remove the apron before leaving controlled areas, following your gowning flow.

- Avoid touching the outer surface to your face or hair when taking it off.

- Place used aprons directly into dedicated laundry bags or bins, not on general furniture.

Short training sessions and clear wall diagrams near gowning rooms help operators build good habits.

Maintenance, laundering and lifecycle management:

ESD performance is not a “once for life” property. It depends on fabric, use and, importantly, how the apron is washed.

Why controlled laundry is important:

ESD fabrics rely on a balance of conductive fibers and surface properties. Uncontrolled washing can:

- Damage or break conductive yarns

- Coat fibers with residues from strong detergents or fabric softeners

- Change surface resistance so the apron no longer meets the static dissipative range

Standards like IEC 61340-4-9 define how to measure the resistance of garments. Guidance from ESD experts highlights the need for periodic testing of ESD clothing to make sure it stays within the defined limits over time.

A proper ESD garment laundry process will control water quality, chemistry, temperatures and mechanical action, and will separate ESD and cleanroom garments from general workwear.

Inspection and testing routines:

You do not need to test every single apron every week, but you do need a clear plan:

- Visual checks during sorting to remove torn, stained or damaged aprons

- Periodic resistance tests on samples of aprons per batch or per time period, according to IEC 61340-4-9 methods

- Defined limits for when an apron is removed from service, for example after failing a test, after a set number of cycles, or when contamination cannot be removed

Recording these checks helps a lot during customer or regulatory audits.

Rental and circular approaches vs in-house management:

Managing ESD aprons fully in-house means:

- Buying stock and trying to guess quantities and sizes

- Organizing washing, testing and repairs

- Dealing with losses, misuse and untracked disposal

With a rental or service model:

- Aprons are supplied to your agreed specification and quantities

- Washing, inspection, ESD testing and repairs are handled by the service provider

- End-of-life garments are retired in a controlled way and directed into recycling or other responsible routes where possible

This reduces the workload on your own team, improves traceability and supports your sustainability goals.

How Lindström supports your ESD apron and garment strategy:

At Lindström, we work with electronics manufacturers, diagnostics labs and pharma plants across the country. We see ESD aprons as a simple but powerful part of a well-run garment system.

Correct specification and selection:

We start by understanding your processes, products and risk profile. Then we help you:

- Define where an esd apron is sufficient and where a full coat or coverall is better

- Select suitable fabrics and designs for your cleanroom class, ESD program and climate

- Standardize apron specifications across multiple Indian sites so everyone works to the same rules

We can also support joint trials on your lines so operators can give feedback on comfort and usability before final decisions.

Validated washing and decontamination:

Your aprons are washed in our controlled laundries:

- Processes are designed specifically for ESD and cleanroom garments, not mixed with general workwear

- Parameters are validated to protect both static performance and low-lint properties

- Loads are tracked so we know how many cycles each garment has gone through

This gives you confidence that the aprons hanging in your gowning room still perform as expected.

Repairs, replacements and inventory management:

We take care of the day-to-day lifecycle:

- Removing damaged or out-of-spec aprons from circulation

- Repairing small defects where appropriate

- Keeping size and quantity levels aligned with your headcount and shift patterns

You avoid piles of surplus aprons in one area and shortages in another, and you do not need to chase petty cash for emergency purchases.

Compliance and documentation for inspections:

Finally, we support your quality and EHS teams with:

- Documentation of garment specifications and test methods

- Evidence of washing, inspection and replacement routines

- Support during customer visits and audits when questions arise about cleanroom esd garments and PPE

Our goal is to be a practical partner who helps you keep both auditors and operators happy.

Conclusion:

An esd apron is a simple piece of fabric that sits between your people and your product. When it is chosen and managed properly, it helps control static and particles, reduces micro-damage to PCBs and devices, and looks solid in front of auditors. When it is chosen casually, or washed anywhere that has space, it can quietly become a weak link.

By checking fabric technology, ESD standards, design and comfort, and by setting up sensible gowning and laundry routines, your team can turn the ESD apron into a reliable front-line barrier in Indian electronics, diagnostics and pharma environments. A managed rental service then keeps that system running smoothly over the long term.

If you would like to review your current ESD apron strategy, reach out to our team at Lindström India.

Frequently Asked Questions:

When should I choose an ESD apron vs an ESD coat?

An ESD coat is better when you need full torso and arm coverage, for example on high risk PCB lines or in stricter cleanrooms. An ESD apron works well in support areas, labs and assembly lines where the main risk comes from the front of the body and where mobility and ease of use are important. Many Indian sites use both, with coats in core EPAs and aprons in nearby test or support zones.

Can ESD aprons be worn over non-ESD clothing?

Yes, that is exactly the idea. An esd apron is designed to sit over normal clothing and block some of the static and particles coming from shirts, sarees or trousers. The key is that the apron itself must be ESD tested and low-lint, and it must be combined with proper footwear and flooring. A rental partner can help ensure the apron keeps its performance even when worn over many different outfits.

How do I know if an ESD apron still works?

You cannot see ESD performance by eye. The only reliable way is to test resistance using methods from standards like IEC 61340-4-9 for garments, either in-house or through a service provider. Visual checks still matter, though. If an apron is badly worn, torn, stained or feels very rough, it is a good candidate for removal and replacement.

Are there ESD aprons suitable for pharma environments?

Yes. There are ESD aprons designed as part of cleanroom esd garments, using low-lint fabrics and clean seams that suit pharma and diagnostics environments. In higher grade areas you may combine them with coats, coveralls and hoods, while in lower grade labs an apron over scrubs is sometimes enough. At Lindström India we help you choose options that fit both your contamination control strategy and your ESD needs.

What is the difference between an ESD apron and an antistatic apron?

An antistatic apron is a broad term for any garment that reduces static build up. An ESD apron is normally part of a formal ESD control system and is tested against standards such as IEC 61340-5-1 and IEC 61340-4-9 to ensure its resistance stays in a defined dissipative range. When you buy for electronics or critical diagnostics work, always ask for clear ESD garment test data, not just “antistatic” claims.

How often should ESD aprons be washed and replaced?

Wash frequency depends on soil level and cleanroom requirements, but many Indian plants send aprons for washing after every shift or every few days of use. Replacement depends on visual condition and ESD test results. In a rental setup, these rules are built into the service. Aprons are taken out of circulation once they reach predefined limits, which keeps you away from guesswork.

Can we share ESD aprons between shifts?

Sharing aprons between shifts is common, especially with a managed service that handles regular washing and distribution. The important points are hygiene, correct sizing and tracking of how often each apron is washed and tested. A structured rental model makes this easier, since garments move through a controlled cycle rather than being left on hooks for anyone to grab.