Yes. Low humidity increases static buildup. ESD garments with hygroscopic fibers help reduce this risk.

17.02.2026

What Makes an ESD Coat ESD-Safe?

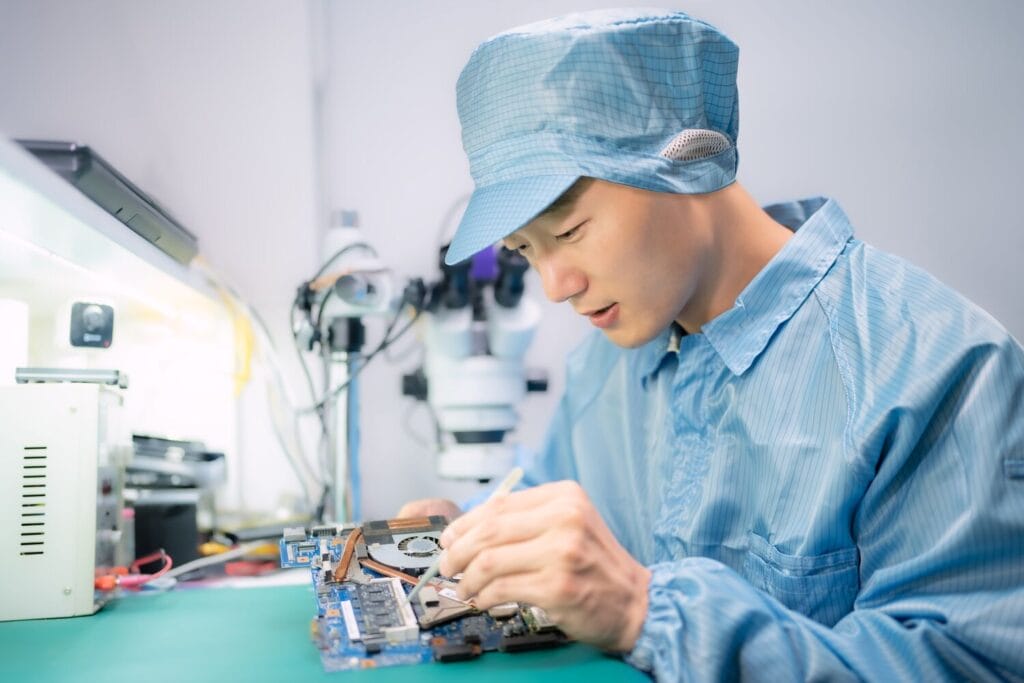

Electrostatic discharge (ESD) control clothing plays a critical role in protecting workspaces from static-related damage, especially in environments handling sensitive electronic components. In cleanrooms, PCB assembly units, semiconductor manufacturing, robotics labs, and SMD production areas, even a small static discharge—often too minor to feel—can damage low-voltage components.

ESD-safe lab coats, jackets, and aprons are engineered to dissipate static safely and maintain a controlled ESD environment. Whether it’s a unisex lab coat, an ESD-safe apron, or a full cleanroom garment, these products help prevent charge buildup, reduce product failures, and protect valuable electronics.

Understanding ESD and Its Impact:

Electrostatic discharge (ESD) is the rapid transfer of electrical charge between two objects with different electrical potentials.

Here’s how it works:

When two materials come into contact and separate—like walking across a carpet in plastic shoes—electrons transfer between surfaces. One becomes positively charged, the other negatively charged. That imbalance creates static electricity.

When the charged object touches or comes close to a grounded surface, the stored energy releases suddenly as an ESD event.

Sometimes you see a spark.

Sometimes you feel a zap.

Sometimes it happens silently.

But even if you don’t feel it, the damage potential is real.

Why ESD Is Dangerous in Electronics & Industrial Environments?

Here’s the critical fact:

- Humans typically feel static discharge at 3,000 volts.

- Sensitive semiconductors can be damaged at as low as 30 volts.

That’s 100 times lower than human perception.

In semiconductor manufacturing, SMD assembly, robotics labs, and cleanroom environments, ESD can:

- Melt microscopic circuitry

- Corrupt integrated circuits

- Cause latent defects (failures later in product life)

- Lead to costly production delays

- Increase warranty claims

- Damage brand reputation

That’s why ESD jackets, lab coats, and aprons are essential—not optional.

Materials Used in ESD Coats:

Conductive Fibers and Their Properties:

What makes an ESD coat truly effective?

It comes down to conductive fibers woven into the fabric.

Common conductive materials include:

- Carbon fiber (most common, cost-effective, black grid lines)

- Copper fiber (higher conductivity, premium applications)

- Silver-metallized yarns

- Stainless steel microfibers

These fibers create pathways that allow static electricity to dissipate safely to ground instead of accumulating on your body.

Surface Resistivity Standards:

Quality ESD garments maintain surface resistivity between:

10⁶ to 10⁹ ohms

This controlled dissipation prevents sudden discharge spikes.

For woven fabrics: Conductive fibers must be spaced no more than 5 x 5 mm grid pattern.

For knitted fabrics: Fibers are integrated directly into the stitch pattern.

Even seams use conductive stitching to ensure panel-to-panel continuity.

Blended Fabrics for Comfort and Performance:

You might wonder why ESD coats aren’t 100% carbon fiber.

Because comfort matters.

High-quality ESD garments blend:

- Polyester

- Cotton

- Hygroscopic synthetic fibers

- Carbon or conductive threads

This combination provides:

- Breathability

- Durability

- Moisture control

- Long-term comfort

- Static dissipation

Some fabrics even include moisture-absorbing properties to reduce static buildup in low-humidity conditions.

The result? A garment that protects your electronics without feeling like a restrictive suit.

Key Design Features of ESD Coats:

Effective ESD garments include:

- Lapel collar for better upper-body coverage.

- Snap-adjustable cuffs (3-snap closure common).

- Full-length knee coverage.

- Patch pockets (2 bottom, 1 chest).

- Conductive grid pattern (Faraday cage effect).

- Groundable snap connectors.

- Shoe cover compatibility.

- Unisex sizing options.

- Durable wash resistance (up to 100 cycles).

The integrated grid pattern creates a Faraday cage effect, helping block external static fields and contain internal charge.

Groundable snaps allow integration with:

- Wrist straps

- Heel grounders

- ESD flooring systems

Standards and Certifications to Look For:

To ensure your ESD coat is truly compliant, look for:

- ANSI/ESD S20.20: Defines ESD control program requirements.

- IEC 61340-5-1 / EN 61340-5-1: International standard for protective clothing in ESD environments.

- ANSI/ESD STM 2.1: Tests garment surface resistance.

- RoHS & REACH Compliance: Ensures environmental safety standards.

Always check for the ESD protective symbol on the garment label.

Proper Maintenance of ESD Coats:

To maintain performance:

- Wash at low temperatures

- Avoid fabric softeners

- Do not use bleach

- Air dry or low-heat dry

- Test resistance regularly

Improper washing can damage conductive fibers.

Conclusion:

ESD coats use conductive fibers in blended fabrics to provide safe charge dissipation. With groundable snaps, full coverage, and compliance with ANSI and IEC standards, they protect your assembly lab, semiconductor production line, and robotics workspace from invisible threats.

In ESD-sensitive environments, proper gear prevents costly damage. Pair your ESD coat with wrist straps, grounded workstations, ESD flooring, and Staff training. Investing in certified ESD-safe apparel protects your electronics—and your bottom line.

Rent ESD Coat

Compliant ESD uniforms, always available when you need them.

Frequently Asked Questions:

add

What are the key differences between antistatic and ESD-safe standards?

Antistatic (EN 1149) tests only surface material and allows resistance up to 10¹¹Ω. ESD standards (EN 61340-5-1) test the entire garment and require stricter resistance under 10⁹Ω plus charge decay testing.

Antistatic prevents sparks. ESD-safe protects sensitive electronics.

add

Why must an ESD coat be grounded?

Because conductive fibers only provide a pathway. Without grounding, charges accumulate instead of dissipating. Proper grounding ensures safe discharge.

add

What materials make a coat truly ESD-safe?

Carbon-infused polyester, stainless steel threads, silver yarns, and conductive mesh grids spaced within 5×5 mm.

add

How often should I test my ESD coat?

Test monthly or before shifts in high-risk environments using a resistance meter per ANSI/ESD STM2.1 guidelines.

add

Are ESD coats reusable after washing?

Yes, if washed correctly. Most high-quality coats withstand 50–100 wash cycles.

add

Can I wear regular clothes under an ESD coat?

Yes, but avoid wool or highly static-prone fabrics. The ESD coat must cover inner garments completely

add

Do ESD coats protect against electrical shocks?

No. They protect against static discharge—not high-voltage electrical hazards.

add