Understanding the basics of gowning and gloving

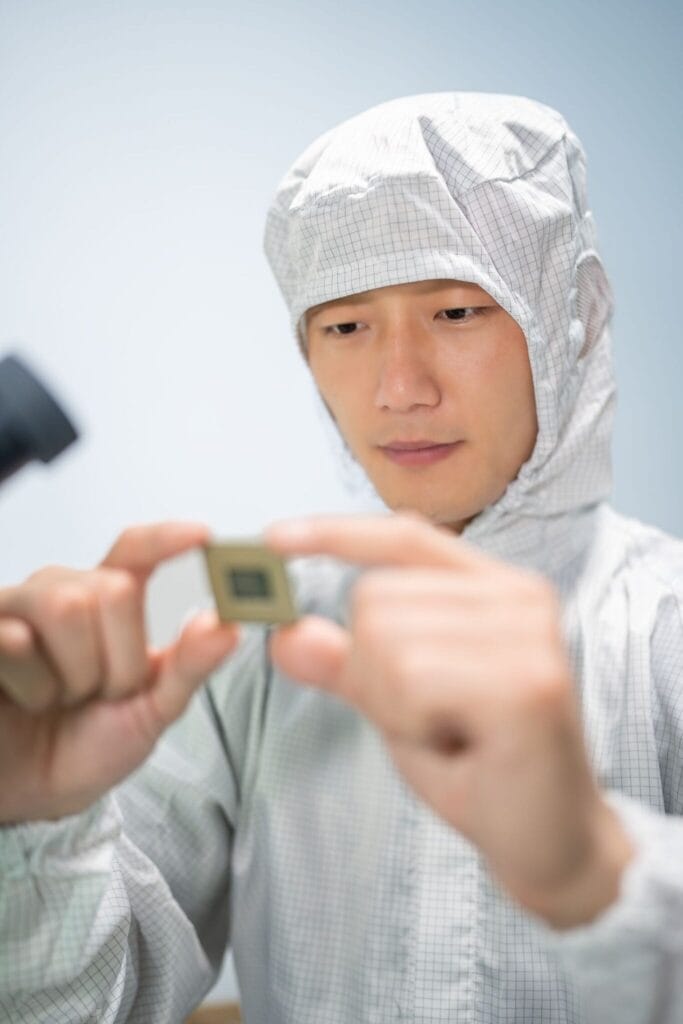

In cleanrooms and pharmaceutical environments, sterility is a requirement. Every movement, material, and procedure must support cleanliness. Among the most important routines are gowning and gloving. These practices create a barrier between people and the critical processes or products they handle. Done correctly, they reduce contamination risks and uphold strict hygiene standards.

Quick summary: the essentials of gowning and gloving:

- Gowning and gloving are critical in cleanrooms and pharmaceutical environments to prevent contamination and maintain sterility.

- Proper technique and training help reduce the risk of introducing harmful particles or microorganisms.

- Mistakes in procedure, such as touching surfaces during gowning or using damaged gloves, can compromise the sterile field.

- Lindström provides hygienically maintained garments, RFID-tracked for compliance and efficiency in cleanroom operations.

- Ongoing training and audits are essential for maintaining high standards and reducing risks.

Why does gowning and gloving matter?

Even a single particle can compromise a product batch, delay research, or trigger regulatory issues. Gowning and gloving provide the first line of defence. They ensure that personnel don’t bring in contaminants from the outside or spread them during work.

From pharmaceutical manufacturing to biotech labs, gowning and gloving procedures form a key part of good aseptic practice. That’s why training, discipline, and the right gear are essential.

The role of gowning in aseptic technique

Gowning starts with selecting the right garments. These should match the environment’s classification: what’s required in an ISO Class 5 cleanroom differs from a Grade C area. The donning process follows a strict order, often from head to toe, to cover all skin and clothing.

Typical gowning components include:

- Hair and beard covers

- Goggles or face shields

- Cleanroom hoods

- Coveralls or gowns

- Boots or shoe covers

Each piece must be handled with care to avoid contamination. Gowning should always take place in a designated change area, where airflow and layout are designed to support cleanliness.

What you need to know about gloving

Once gowning is complete, gloves come next. Gloves must be sterile and free from pinholes or defects. The choice of material—latex, nitrile, or vinyl—depends on the application and user sensitivities. Nitrile is a popular choice for chemical resistance and comfort.

Key gloving steps include:

- Wash and dry hands thoroughly before gloving

- Inspect gloves for tears or particles

- Avoid touching the outer surface during donning

- Use proper removal techniques to avoid cross-contamination

Many facilities require double-gloving, with an inner and outer pair, especially in high-risk environments. This extra layer adds safety and allows for glove changes without full re-gowning.

Common gowning and gloving mistakes

Mistakes in sterile environments have real consequences. Some of the most common errors include:

- Donning items out of sequence

- Touching contaminated surfaces during gowning

- Wearing gloves with small tears or holes

- Not fully covering sleeves or wrists

- Removing gloves in a way that spreads contaminants

Each of these compromises the sterile field. Addressing them requires more than one-off training—it takes continuous practice, observation, and feedback.

Best practice: training and compliance

Regular training is essential to reinforce correct technique and explain why it matters. When people understand the impact of a single misstep, they’re more likely to follow the process closely.

In addition to training, cleanroom environments benefit from:

- Visual aids and signage in gowning rooms

- Routine audits and observational checks

- Clear feedback loops to correct behaviour

When everyone understands and respects the process, contamination risks drop significantly.

Stay compliant by partnering with Lindström

At Lindström, we support pharmaceutical and cleanroom operations with reliable, hygienically maintained cleanroom garments. Our cleanroom service includes:

- Professionally laundered and sterilised garments

- RFID tracking for traceability and compliance

- Inventory planning and delivery that ensures availability

We also design our garments for comfort and usability; because the best PPE is the one people actually wear correctly. With our service, you reduce contamination risks while saving time and resources.

Checklist: is your gowning and gloving process up to standard?

Here’s a simple checklist to help review your current procedures:

- Do garments match the cleanroom classification?

- Are gloves the correct type for your tasks?

- Are training sessions held regularly and logged?

- Are donning and doffing areas clearly marked and controlled?

- Are garments cleaned, maintained, and replaced professionally?

- Do you track inventory and usage effectively?

If you answered “no” to any of these, it may be time to review your current setup, or consider outsourcing for peace of mind.

FAQ – Common questions about gowning and gloving:

What is the importance of gowning and gloving in sterile environments?

How do gowning and gloving contribute to infection control?

What are the key steps in the gowning process?

Why is the gloving process important in maintaining sterility?

What are common challenges in gowning and gloving?

How does Lindström help me with gowning and gloving solutions?

Lindström offers advanced cleanroom and workwear services that enhance safety, compliance and efficiency. Partnering with us, your garments are tracked with RFID tags, for compliance and inventory management, setting high standards for sterile environments.