Implementing Effective Hygiene Practices in the Pharmaceutical Industry

Adherence to stringent hygiene protocols in the pharmaceutical industry is critical to prevent any form of contamination affecting the quality of medicinal products. Delivering pharmaceutical products of the highest quality requires maintaining rigorous hygiene and cleanliness standards throughout all stages of manufacturing, from personnel working in the manufacturing unit to the production process.

Pharmaceutical companies are necessitated to comply with strict hygiene regulations to ensure that drugs are manufactured and packaged in a contamination-free environment. The discussion here encompasses vital hygiene practices that companies should incorporate.

Hygiene in Production:

GMP-compliant production units necessitate the implementation of custom hygiene protocols to facilitate the safe production and use of products in life science, biotechnology, cosmetics, and medical applications.

To prevent contamination and achieve the highest sanitation standards, pharmaceutical companies must promote the use of classic, sterile, or microbial-filtered disinfectants alongside manual disinfection practices. Progressive hydrogen peroxide vapour generators can streamline hygiene maintenance in production facilities. These robust machines enable swift and efficient decontamination of the manufacturing unit and equipment.

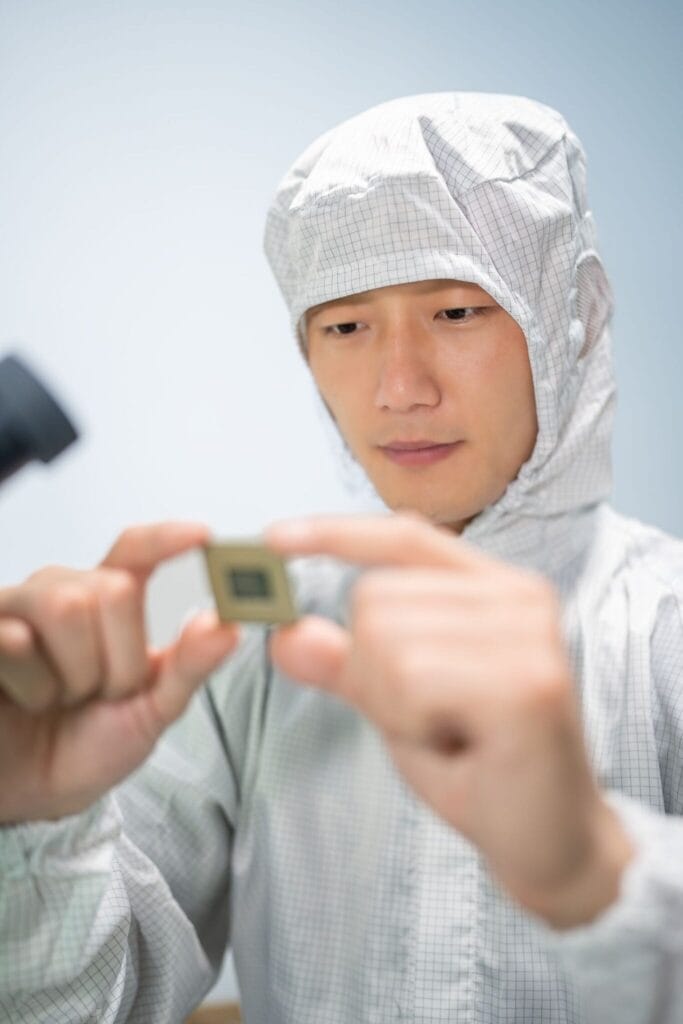

Furthermore, cleanroom concepts, with an emphasis on pharmaceutical garments and cleanroom suits, have garnered significant popularity in the pharmaceutical domain. Controlled environments designed for specialized pharmaceutical manufacturing maintain low airborne microbes, dust levels, chemical vapours, and aerosol particles.

Thorough premises inspection during the loading or unloading of medicinal products helps flag potential contamination hotspots, which can then be cleaned with lab-tested, industry-compliant disinfectants. Companies can minimize contamination risks by using cemented storage areas and walkways alongside medical laboratory uniform and other protective equipment.

Personnel Hygiene:

Arguably, humans are primary sources of contamination, even with measures to maintain hygienic production facilities, equipment, raw materials, and product packaging. Owning a state-of-the-art manufacturing unit or stringent quality control measures will not result in superior hygiene in the pharmaceutical industry without trained personnel responsible for ensuring high sanitation standards and product quality.

One of the crucial methods to maintain personnel hygiene is the mandatory implementation of hygienic workwear in specific work areas such as production facilities and storage areas. Ensuring workers are equipped with pharma uniforms, laboratory uniforms, hats for covering scalp hair, and snoods for moustaches and beards helps maintain hygiene. Proper training regarding the use and maintenance of uniforms should be provided, alongside clarifying guidelines on where these uniforms should not be worn, like canteens, smoking areas, and toilets.

Workwear laundering should align with industry-defined criteria, ensuring effective clothing segregation, rigorous workwear cleaning, and contamination-free packaging. Proper verification and validation of the laundry process are pivotal. Implementing high-performance hand disinfectants and dispensing systems is a critical preventive measure against germ and impurity transmission via personnel hands.

Plant and Surface Disinfection:

Additionally, effective plant and surface disinfection procedures, employing high-quality, industry-approved sterilization products that are user-friendly and promote occupational safety, should be practised. Regular cleaning and scrubbing of plant walls, ceilings, and floors prevent impurity accumulation and contamination spread.

Performance Monitoring for Maintaining Pharmaceutical Hygiene:

Effective monitoring is a critical aspect of maintaining pharmaceutical industry hygiene standards. Simply implementing hygiene strategies is not enough; performance monitoring of the measures implemented is vital. Tools and products enabling comprehensive and accurate hygiene monitoring across the entire manufacturing, storage, and cleaning process can quickly and conveniently streamline hygiene performance monitoring.

Effective hygiene practices of medical laboratory uniform in the pharmaceutical industry ensure the safety of customers and employees alike. It aids in proactive contamination prevention and upholding a clean and germ-free environment.

Frequently Asked Questions (FAQ)

Why are effective hygiene practices essential in the pharmaceutical industry?

Effective hygiene practices are crucial to prevent contamination that can compromise the safety and efficacy of medicinal products. To protect customers and employees and uphold product quality plus regulatory compliance, a germ-free, clean environment is maintained.

What role do medical laboratory uniforms play in maintaining hygiene?

Medical laboratory uniforms serve as protection from contaminants because they help prevent contamination proactively. A sterile environment within pharmaceutical settings well-kept uniforms help uphold.

How important is performance monitoring in pharmaceutical hygiene?

Performance monitoring is important to ensure hygiene measures are properly enacted. Products and tools monitor hygiene accurately and comprehensively across cleaning, storage, and manufacturing processes. They help streamline hygiene performance, so they maintain high standards.

What are the key areas to focus on for improving hygiene in pharmaceutical settings?

The four key areas include production hygiene, personnel hygiene, plant and surface disinfection, and performance monitoring. Focusing on these areas helps maintain optimal sanitation standards and ensures the quality of pharmaceutical products.

How does Lindström support pharmaceutical companies in maintaining hygiene standards?

Lindström provides professional workwear rental services because it offers clean along with disinfected uniforms for ensuring employee safety plus improved product quality. Their services for cleanroom support companies in pharmaceuticals through production facilities that are hygienic. The services do also provide for decontaminated garments.

Why is documentation important in hygiene performance monitoring?

Proper documentation is essential for due diligence. Maintaining records of cleaning and decontamination processes helps evaluate, update, and communicate hygiene standards within the company, ensuring that responsibilities are clearly understood, and standards are upheld.

What measures can be taken to prevent contamination through personnel?

Implementing strict personal hygiene protocols, providing appropriate and hygienic workwear, and ensuring regular training on hygiene standards are vital measures. These steps help minimize the risk of contamination introduced by personnel in pharmaceutical manufacturing environments.