How to properly gown for a cleanroom environment?

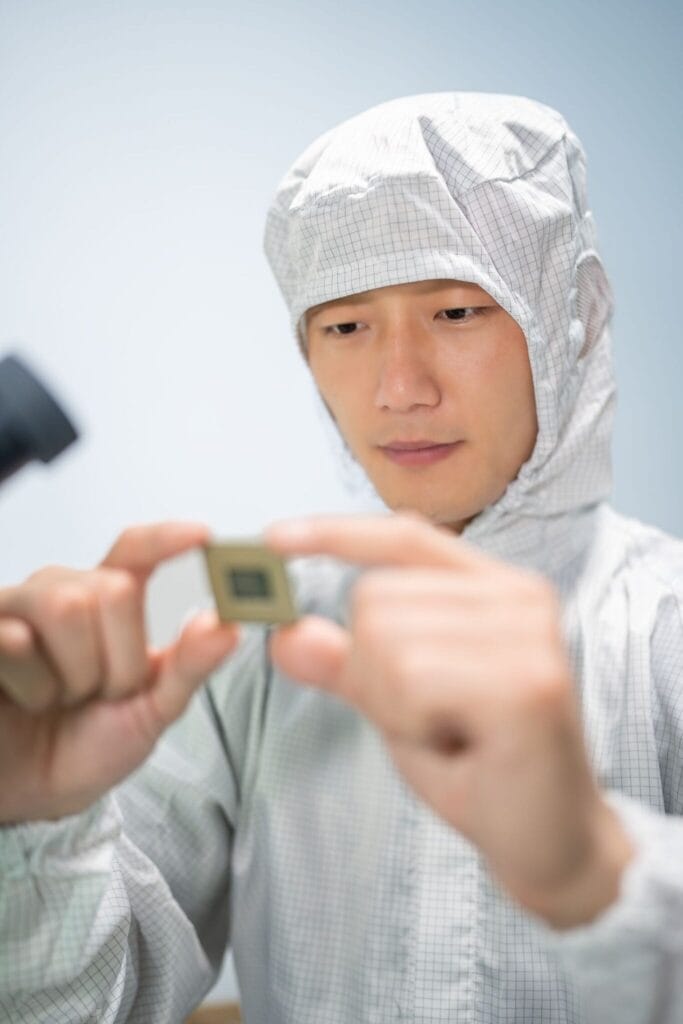

Introduction to cleanroom gowning

Did you know that nearly all cleanroom contamination stems from personnel? In industries where sterility is critical, mastering proper gowning isn’t just important—it’s essential for operational success.

In environments where sterility is crucial, like those in the pharmaceutical and electronics industries, mastering the art of cleanroom gowning is essential. Proper gowning techniques are the first line of defense against contamination, ensuring the integrity of products and the safety of personnel. This guide provides you with a comprehensive understanding of the gowning procedures necessary for maintaining a controlled cleanroom environment. By following these steps, you can expect to enhance product safety, regulatory compliance, and operational efficiency.

Before diving into the gowning process, it is important to gather the necessary materials and understand the tools involved. This will lay a solid foundation for a seamless gowning experience. Let’s explore the essential materials and steps to achieve optimal cleanroom attire.

What you need for cleanroom gowning

Before beginning the gowning process, it’s crucial to have the right materials at hand. The key components include cleanroom garments such as coveralls, gloves, masks, goggles, and boots. Each piece of attire plays a significant role in preventing contamination. Depending on the specific requirements of your cleanroom, additional accessories like hoods or aprons may be needed.

Partnering with a reliable textile service provider can ensure that the garments in use meet the highest standards of hygiene and sterility. Lindström provides customized workwear solutions designed to suit industry-specific needs, ensuring compliance with stringent cleanliness standards. Cleanroom services offered by a reliable partner, such as Lindström, include laundering and tracking ensure garments meet the highest standards of hygiene and sterility.

Step 1: Preparing for gowning

Preparation is a critical step in the gowning process, because even small lapses can compromise sterility and product safety. Begin by washing hands thoroughly with an antiseptic soap to remove any trace of contaminants. This step is non-negotiable, as hands are a common source of contamination. Use a lint-free towel to dry the hands.

Next, don the required undergarments, if specified by the cleanroom’s protocol. These usually include lint-free garments that act as an additional barrier against particulates. Ensure that all the necessary cleanroom attire is available and laid out in the correct order, ready for donning. This preparation step helps streamline the gowning process, making it efficient and effective.

Step 2: Donning cleanroom attire

Begin with the coverall, carefully stepping into it and securing it from the bottom up. Ensure the coverall fits snugly but comfortably, covering all street clothes. Next, put on the boots, ensuring they cover the legs of the coverall. Fasten any straps or snaps securely to prevent any gaps.

Proceed to wear the mask, ensuring it fits tightly around your nose and mouth. If the cleanroom protocol requires, put on a hood to cover your hair completely. Finally, don the gloves, ensuring they go over the sleeves of the coverall. This overlapping creates a continuous barrier, reducing the risk of skin exposure.

Step 3: Final inspection and adjustments

Once fully gowned, perform a thorough visual inspection. Check for any visible tears, gaps, or improperly fastened areas in your attire. Adjust as necessary to ensure complete coverage. This final check is crucial in maintaining the integrity of the cleanroom environment.

Ask a colleague or use a mirror to inspect areas that are challenging to see on your own. Ensure that the gloves, mask, and goggles are snug and secure, providing a complete seal against potential contaminants. Taking the time for these inspections prevents lapses in protection.

Tips and best practices for effective gowning

To improve the gowning effectiveness, always follow the cleanroom gowning procedures specific to the environment. Regularly review and update these procedures to align with the latest industry standards and best practices. Consider incorporating a checklist to ensure nothing is overlooked during the process.

Training is invaluable. Engage in regular training sessions and refreshers to keep skills sharp.

Common gowning challenges

One common challenge in gowning is the potential for tearing garments during donning. To mitigate this, ensure that all movements are deliberate and gentle. Choosing the right size and fit for the cleanroom attire can also reduce this risk.

FAQs often revolve around maintaining the sterility of garments. It’s important to store cleanroom attire in designated areas, away from high-traffic zones. Regular laundering by specialised services ensures garments remain contaminant-free and ready for use. Outsourcing your garment management is a good way to ensure that garments are taken care of in the designated and compliant way.

Mastering cleanroom gowning

By mastering cleanroom gowning, you are not just safeguarding your products and personnel—you are setting a benchmark for operational excellence in sterile environments.

We encourage you to apply these insights and explore our cleanroom services for tailored solutions that uphold the highest standards of hygiene and sustainability. Embrace the future of cleanroom gowning with confidence, knowing we’re equipped with the expertise and support necessary for success.