Guide to donning and doffing cleanroom garments efficiently

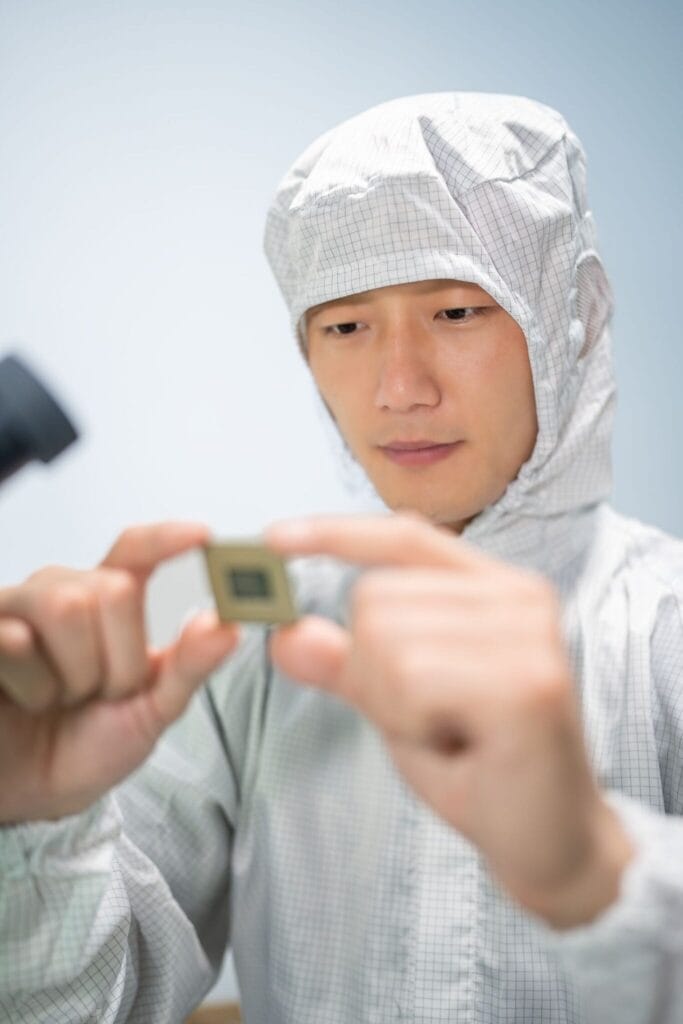

When it comes to maintaining a pristine environment in industries like pharmaceuticals and electronics, every detail matters—especially the way we handle cleanroom garments. Properly donning and doffing these garments is not just a routine task; it’s a critical process that ensures the integrity of the cleanroom and protects both the product and personnel from contamination. This guide is tailored for cleanroom operators, managers, and quality professionals seeking to optimise gowning procedures. By following a structured approach, you can enhance cleanliness, safety, and efficiency in your operations.

Essential tools and materials needed

Before stepping into the cleanroom, gather all necessary garments and tools. Each item plays a role in maintaining a contamination-free environment:

- Cleanroom suits: Act as a protective barrier against particulate and microbial contamination.

- Gloves: Ensure a barrier against microbial transfer.

- Masks and hoods: Minimise the risk of contamination from hair and respiratory droplets.

- Shoe covers: Prevent particulate contamination from footwear.

- Goggles or face shields (for specific classifications): Provide additional protection against splashes and particulates.

- Gowning checklist: Ensures all required items are accounted for and donned in the correct sequence.

Designate a gowning area equipped with benches, mirrors, and hand sanitizers to facilitate the process. Ensure all garments meet GMP Annex 1 or ISO 14644 standards for material quality and cleanliness.

Step 1: Preparing the cleanroom environment

Before donning your cleanroom garments, ensure the environment is ready:

- Clean and sanitize the gowning area to prevent contaminants from transferring to garments.

- Verify the airlock or gowning room complies with ISO 14644-1 cleanliness standards for air quality.

- Stock all necessary garments and tools to ensure availability.

- Check for air drafts or open doors that might introduce particles into the cleanroom.

Proper preparation sets the stage for a successful gowning process.

Step 2: Correctly donning cleanroom garments

Follow these steps to ensure proper donning:

- Wash and sanitize your hands thoroughly to remove any contaminants.

- Don the bouffant cap or hood to cover your hair completely.

- Wear the mask, ensuring a snug fit over the nose and mouth.

- Put on the cleanroom suit, ensuring it is securely zipped or snapped.

- Wear gloves, ensuring they overlap and cover the cuffs of the suit.

- Don shoe covers, avoiding contact between your hands and the floor.

- Wear goggles or face shields, ensuring they fit securely without gaps and do not fog up during use.

- Check your gowning in the mirror to confirm proper fit and alignment.

Each step should be performed carefully to maintain cleanliness and prevent contamination.

Step 3: Properly doffing cleanroom garments

Doffing cleanroom garments is equally critical to avoid reintroducing contaminants into the environment. Follow these steps:

- Remove shoe covers, taking care not to touch their external surface.

- Remove gloves, turning them inside out to contain contaminants.

- Carefully remove the cleanroom suit, avoiding contact with the external surface.

- Take off the goggles or face shield, holding them by the straps and avoiding contact with the lenses.

- Remove the mask and cap, discarding them or storing as per protocol.

- Wash and sanitize your hands thoroughly after doffing.

Adhere to your cleanroom’s specific procedures for disposal or storage of garments.

Step 4: Post-use garment handling

Once garments are doffed, proper handling is vital:

- Reusable garments: Place them in designated bins or send them to a compliant laundry service, such as Lindström, for cleaning and sanitization.

- Single-use garments: Dispose of them following your company’s waste management protocols to prevent contamination.

Partnering with a cleanroom service provider like Lindström ensures proper garment lifecycle management, reducing environmental impact while maintaining compliance.

Tips and best practices for garment efficiency

To enhance efficiency, consider implementing a checklist system for donning and doffing procedures. This can reduce errors and ensure consistency. Regular training sessions for cleanroom staff can also help reinforce the importance of each step and keep everyone aligned with best practices.

Using high-quality garments that are specifically designed for your industry can make the process smoother and more efficient. Additionally, employing garment tracking systems—like those offered by Lindström—can provide insights into usage patterns and help manage inventory more effectively.

Troubleshooting common challenges

Despite careful preparation, gowning can present several challenges:

- Ill-fitting garments: Employees may struggle with garments that are too tight or too loose, leading to discomfort and potential breaches in cleanliness. Regular sizing checks and the provision of garments in a range of sizes can mitigate this issue.

- Accidental contamination: Mistakes such as touching a contaminated surface or incorrect sequencing of gowning steps are common. Establishing clear visual aids and step-by-step training can help reduce these errors.

- Delays in gowning: Congestion in the gowning area or poor organisation can slow down the process, affecting operational efficiency. Optimise the layout of the gowning area by designating zones for specific tasks and ensuring an adequate supply of garments.

- Garment cleanliness: If garments appear soiled or fail cleanliness checks, it may indicate issues in laundering or storage. Partnering with a reliable service provider ensures all garments are cleaned to appropriate standards.

- Improper doffing technique: Errors during doffing can lead to contamination of the individual or the environment. Reinforce training on doffing sequences and consider adding procedural audits to monitor compliance.

By identifying these challenges early and addressing them proactively, cleanroom teams can ensure a smoother, more effective gowning process.

Implementing cleanroom garment procedures

By following the steps outlined in this guide, you’ll be well on your way to mastering the art of donning and doffing cleanroom garments efficiently. These procedures are not just about maintaining compliance—they’re integral to ensuring the safety and cleanliness of your work environment.

We encourage you to implement these practices in your cleanroom activities and explore how our services can further enhance your operational efficiency and sustainability. By doing so, you’ll not only protect your products and personnel but also partner up for more sustainable business operations.

Frequently Asked Questions (FAQ)

How does the design of the gowning area influence donning efficiency?

A well-designed gowning room supports a unidirectional workflow along with floor markings and mirrors plus separation of storage areas going from dirty to clean zones created for used and clean garments. This setup supports intuitive, efficient donning and doffing behavior which reduces cross-contamination risks.

Why is garment material selection important in cleanroom operations?

The material must prevent particle shedding, allow for breathability, and resist microbial penetration. Lindström provides garments made of fabrics specifically engineered for cleanroom conditions, offering both protection and comfort to ensure compliance without compromising productivity.

How can facilities reduce human error during gowning procedures?

Use visual guides, wall-mounted instructional posters, mirror checks, and digital reminders. Incorporating gowning checklists and assigning gowning monitors for high-risk zones also helps ensure adherence to protocols and reduces contamination caused by improper wear.

What roles do cleanroom garment tracking systems play in compliance?

RFID or barcode tracking systems can log garment use, wash cycles, and replacement timelines. Facilities do comply with the ISO cleanroom standards, audit requirements are being met efficiently, and the garments are not overused or missed during the rotation.

How does incorrect doffing impact cleanroom integrity?

Improper doffing can release contaminants from the surface of garments into the air, especially if garments are removed too quickly or contact exposed skin. Slow, controlled removal—while turning garments inside out—is critical to maintain cleanroom air quality.

Are reusable cleanroom garments more effective than disposable ones?

Reusable garments maintained by certified laundering services like Lindström’s offer consistent protection, a reduced environmental impact, and lower long-term costs. Disposable suits can seem convenient, yet they often pose risks for tearing. Other issues are inconsistent quality and higher waste.

What audit failures are most linked to gowning issues?

Common failures include lack of documentation on gowning practices, visible skin exposure, poor storage of clean garments, or garments showing signs of wear or contamination. Preventing these requires regular internal audits, proper garment management, and well-trained personnel.