ESD Gloves in India: Critical Tools for Static and Contamination Control

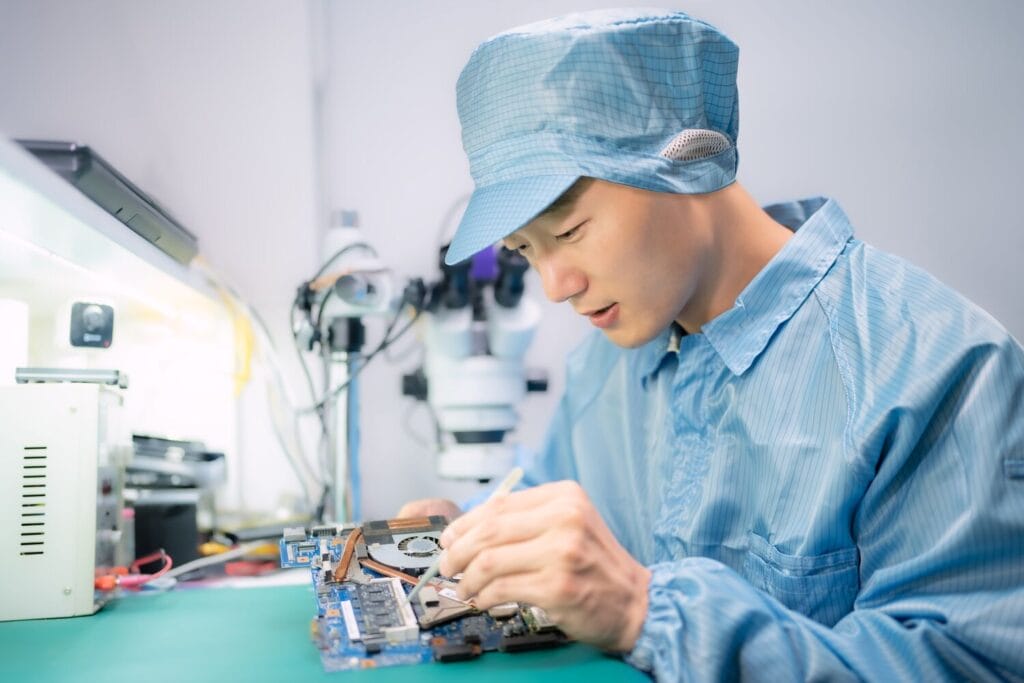

Electrostatic discharge feels harmless when you just get a small shock from a metal door handle. Inside your cleanroom or electronics line, it is a different story. A single uncontrolled discharge can damage a sensitive chip, corrupt a diagnostic device or compromise a pharma batch. This is where the right ESD gloves become essential—often used alongside other protective garments such as an ESD apron to ensure full-body static control in critical zones.

ESD gloves help your operators control static on their hands so it does not jump into your products or equipment. In many Indian facilities, they are now as basic as ESD shoes or coats. When they are chosen and maintained correctly, they protect both electronics and pharma products, and they make audits easier.

In this blog, we will explore what ESD gloves are, how they work, what can go wrong with the wrong gloves, how to choose the right options for your cleanroom in India.

What are ESD gloves and how do they work?

ESD gloves (Electrostatic Discharge Gloves) are work gloves designed to control static electricity on the operator’s hands. They are not electrical-insulation gloves. Instead, they allow static charges to flow away in a controlled manner, usually to an ESD-safe floor and earth connection.

Typical features of ESD gloves:

- Made from synthetic fibers such as nylon or polyester blended with conductive fibers like carbon or copper.

- Sometimes coated on the palm or fingertips with polyurethane (PU) or nitrile for extra grip.

- Designed with a specific surface resistance, usually between 1×10⁵ and 1×10¹¹ ohms, so they safely dissipate static without creating a shock risk for the operator.

When you see “antistatic gloves for electronics”, it usually means gloves that meet IEC 61340-5-1 requirements for ESD protective equipment, which is the main international standard for controlling static around electronic devices.

ESD Gloves are commonly used in:

- Electronics and semiconductor manufacturing.

- Cleanrooms and laboratories.

- Pharmaceutical and medical device production.

- Automotive electronics assembly.

Why are ESD Gloves important?

Human hands are a major source of static electricity. Without proper protection, static discharge can:

- Damage electronic components.

- Cause hidden defects that reduce product lifespan.

- Lead to compliance failures during audits.

- Increase waste and rework costs.

Using certified ESD gloves ensures:

- Controlled static dissipation.

- Product and process safety.

- Compliance with international ESD standards.

Types of ESD Gloves and Materials:

Different applications require different types of ESD gloves. Below are the most commonly used options in India:

| Type of ESD Gloves | Material | Key Features | Typical Applications |

|---|---|---|---|

| ESD Knit Gloves | Nylon / Polyester with carbon fiber | Reusable, breathable, good dexterity | Electronics assembly |

| PU-Coated ESD Gloves | Knit base with PU coating | Enhanced grip, abrasion resistance | Precision handling |

| ESD Nitrile Gloves | Conductive nitrile | Disposable, chemical resistant | Cleanrooms, pharma |

| Carbon Fiber ESD Gloves | Carbon filament blend | High conductivity, durable | High-sensitivity electronics |

ESD Gloves vs Anti-Static Gloves:

Although often confused, ESD gloves and anti-static gloves are not the same.

- Anti-static gloves reduce static generation but may not safely dissipate charge.

- ESD gloves actively control and discharge static electricity within a defined resistance range.

For sensitive electronics and regulated environments, ESD gloves are the recommended choice.

ESD Gloves Standards and Compliance:

When selecting ESD gloves in India, ensure they comply with recognised international standards:

- IEC 61340-5-1 – Protection of electronic devices from electrostatic phenomena.

- ANSI/ESD S20.20 – ESD control programme requirements.

- Surface resistivity range: typically 10⁶ to 10⁹ ohms.

Compliance with these standards is essential for audits, certifications, and global supply chains.

Cleanroom ESD gloves vs Ordinary ESD gloves:

For Indian pharma and electronics cleanrooms, not every ESD glove is suitable. You often need cleanroom ESD gloves, which have two roles:

- Control static charges

- Release very low particles and fibres to protect product cleanliness

These cleanroom ESD gloves are made from low-lint yarns and are processed and packed in controlled conditions. They are often combined with other cleanroom garments India uses for audits, such as coveralls, hoods and overshoes.

For pharma applications, you may also see “pharma cleanroom gloves” that combine ESD properties with chemical resistance or special cleanliness levels, depending on whether the glove is used in Grade A/B or lower grade areas.

What can go wrong with the wrong ESD gloves?

If ESD gloves are missing, poor quality, or incorrectly maintained, they can actually make your ESD and contamination situation worse. This is where we see many issues in Indian cleanroom facilities.

Here are some typical risks.

Electronics and PCB assembly:

In an electronics plant producing PCBs, modules, or diagnostic equipment, the wrong gloves can lead to:

- Latent defects in components: Chips or boards may still pass final test but fail later in the field because of hidden ESD damage.

- Increased scrap and rework: Unseen static events can cause intermittent faults that are hard to trace. Teams spend hours troubleshooting.

- False sense of security: Operators think they are protected because they wear “ESD-looking” gloves, but the material has no tested ESD performance or has lost it after incorrect washing.

- Contamination on lenses and sensors: Fluffy cotton gloves or low-quality knitted gloves can shed fibers on optical surfaces or tiny sensors.

Pharma and medical devices:

In pharma and medical device environments, the wrong glove choice can go beyond product quality and create compliance issues:

- Particle and fibre contamination: Non-cleanroom cotton or latex gloves can shed particles onto tablets, vials, syringes or devices.

- Interference with test results: Residues from poor laundry chemicals or talc from gloves can affect sensitive diagnostics and analytical equipment.

- Regulatory findings during audits: Inspectors increasingly look at how garments and gloves are specified, washed and controlled according to international references like EU GMP Annex 1.

Typical “red flag” glove issues:

We often see the same patterns during site visits:

- Normal knit cotton gloves used where ESD gloves are required.

- “ESD printed” gloves bought online with no real test reports.

- Gloves washed in uncontrolled in-house laundries with fabric softeners and mixed with household textiles.

- Old gloves with worn-out PU coating that have lost their grip and possibly their ESD performance.

- No documented testing of surface resistance over the glove lifecycle.

Each of these cases increases the risk of a static event or contamination, even though everyone thinks they are “doing the right thing” by using gloves.

How to choose the right ESD gloves for your cleanroom in India?

Choosing the right ESD gloves India wide is not only about price or comfort. You need to align them with your ESD control programme, your cleanroom classification, and the reality of long operator shifts in Indian conditions.

Here is a practical checklist.

1. Cleanroom classification and cleanliness:

Start from your cleanroom class and product risk:

- For ISO Class 5 or Grade A/B areas, you usually need cleanroom ESD gloves with very low particle generation and suitable sterilisation or sanitisation routines.

- For ISO 6–8 or Grade C/D environments, you may accept slightly higher particle levels, but still need gloves processed and packed for cleanroom use.

- Check whether the glove supplier or service provider can show particle and fibre data for the gloves in your required class.

2. ESD programme requirements:

Align glove properties with your ESD control plan:

- Ask for test data confirming that glove surface resistance is within the typical 1×10⁵ to 1×10¹¹ ohm range and that testing follows IEC 61340-5-1 or similar methods.

- Confirm that gloves are compatible with your wrist straps, footwear, flooring and work surfaces so the whole ESD system works together.

- Make sure the gloves are labelled and traceable so you know which model is approved in which area.

3. Touch sensitivity and grip:

Operators in pharma and electronics need precise finger control:

- For fine assembly or handling small components, thin knitted gloves with PU-coated fingertips often work best. They give better feel and grip.

- For tasks with larger parts or tools, a full palm coating may give more secure grip.

- Ask your team to trial different options and give feedback on comfort and precision, not only on “softness”.

4. Comfort in India’s climate:

Long shifts in warm, sometimes humid conditions are common in Indian plants:

- Choose breathable materials and correct sizes so hands stay as dry as possible.

- Consider lighter glove weights for non-critical areas and slightly thicker options for tasks that need more mechanical protection.

- Ensure cuffs are snug but not tight, especially for operators wearing gloves for 8–12 hours.

5. Fit with your full cleanroom garment system:

ESD gloves should work together with your full set of cleanroom garments India requires for audits and exports:

- Check that glove cuffs overlap with sleeves to avoid exposed skin.

- Make sure operators are trained to don gloves after garments to avoid contamination.

- Align colours or markings of gloves with zones so it is visually clear if the wrong glove appears in a high-risk area.

6. Lifecycle cost and sustainability:

Lowest unit price is rarely the lowest cost:

- Look at how many washes or uses the glove can handle while keeping its ESD and cleanliness performance.

- Include the cost of laundry, testing, sorting and waste when comparing disposable and reusable options.

- Consider a managed esd workwear rental or glove service where you pay for the service level, not each individual glove.

Maintenance, laundering and lifecycle management:

Choosing a good glove is only half the job. How you wash, inspect and replace ESD gloves has a direct impact on safety and compliance.

Why controlled laundering matters:

Uncontrolled washing can damage the conductive fibres in ESD gloves or leave residues that change their surface resistance:

- Household detergents and fabric softeners can coat the fibers and increase resistance, so the glove no longer dissipates static correctly.

- High drying temperatures can damage PU or nitrile coatings and shorten glove life.

- Washing gloves together with normal cotton workwear spreads lint back onto “clean” gloves.

A validated laundry process for ESD gloves will typically:

- Use controlled water quality, detergents and temperatures.

- Avoid fabric softeners and other chemicals that interfere with ESD performance.

- Include specific cycle parameters for cleanroom ESD gloves versus more general workwear.

- Dry and handle gloves in a way that minimizes particle contamination.

Inspection and testing:

Regular inspection and testing keep unsafe gloves out of your cleanroom:

- Visual checks to remove torn, heavily stained or damaged gloves.

- Periodic testing of surface resistance according to standards such as IEC 61340-5-1 to confirm gloves still sit in the correct resistance range.

- Clear rules on maximum number of wash cycles or service age per glove type.

Having this as a documented routine helps during audits and gives your ESD coordinator more confidence.

Why a rental or service model helps?

Managing all of this in-house can be heavy:

- You need washing capacity, test equipment, trained staff and documentation.

- Stock mistakes are common. Some teams run out of the right sizes while racks are full of old or unapproved gloves.

- Gloves that have lost their ESD properties may stay in circulation simply because nobody checks them.

With a glove and esd workwear rental or service model:

- We supply the right gloves to each area and operator based on your agreed specification.

- We wash, test and inspect gloves in a controlled environment.

- We remove failed or end-of-life gloves from circulation and replace them with compliant ones.

- You get predictable monthly costs instead of surprise repairs or emergency glove purchases.

How Lindström India supports your ESD glove and cleanroom program?

At Lindström, we work with pharma, electronics and cleanroom customers across the country who face exactly these challenges. Our role is to help you design and run a practical, compliant and cost-efficient ESD and cleanroom garment system, including gloves.

Correct specification and selection:

We start by understanding your processes, cleanroom classifications and ESD control requirements. Then we help you:

- Define which ESD gloves and cleanroom garments India needs in each zone.

- Select materials and coatings that suit your products and your operators’ tasks.

- Align glove choices with your wider ESD garments, such as coats, coveralls and ESD footwear.

Because we operate in many industries, we can share what works in similar facilities without forcing a one-size-fits-all solution.

Validated washing and decontamination:

Your gloves are processed in our controlled laundries:

- Wash programs are designed for ESD textiles so their static control properties are kept within the required range.

- We use procedures that minimise lint and particles, suitable for cleanroom esd gloves and pharma cleanroom gloves.

- Each process step is documented so you can show auditors how gloves are handled.

Repairs, replacements and inventory management:

We manage the glove lifecycle for you:

- Gloves are checked at each cycle and removed when damaged or out of spec.

- Stocks are balanced by size and area so your operators always find the right glove ready.

- You avoid over-buying and under-using gloves because we manage circulation and replenishment.

Compliance and documentation:

Our service is designed to support your quality and ESD documentation:

- Clear records of washing, inspection and replacements.

- Support for questions during audits about garments and gloves.

- Integration with your head-to-toe ESD solution, so gloves are not treated as an afterthought.

We aim to be a long-term partner, not just a supplier. The goal is simple: safe products, smoother operations and fewer glove-related surprises for your team.

Conclusion:

ESD gloves are a small item with a big impact in Indian cleanrooms and electronics facilities. The right esd gloves protect sensitive electronics, diagnostics and pharma products from static discharge while also helping you control particles and pass audits. The wrong gloves or poor laundering can silently increase your ESD risk and contaminate critical areas.

By looking at cleanroom class, ESD standards, operator comfort and lifecycle cost, you can choose ESD gloves that truly support your process. When validated washing, inspection and testing are in place, you can trust that every glove on a worker’s hand still performs as specified.

ESD gloves are essential for protecting sensitive products, ensuring compliance, and maintaining process reliability in Indian manufacturing environments.

Choosing the right glove type, material, and standard compliance helps reduce risk while improving efficiency and sustainability.

If you would like to review your current ESD glove strategy and see how a managed glove and garment service could work in your facility, reach out to our team at Lindström.

Frequently Asked Questions:

What is the difference between ESD gloves and normal gloves?

Normal gloves are usually chosen for mechanical protection, cleanliness or comfort. ESD gloves are designed specifically to control static charges on the operator’s hands, so they do not damage sensitive electronics or products. They use special fibers and materials that keep surface resistance within a safe range.

Can I reuse disposable ESD gloves?

Some disposable ESD gloves are designed for single use only, usually where very high cleanliness is required. Others can be reused a limited number of times if they are handled correctly. The key question is not only cleanliness but whether the ESD properties are still within range. This is easier to guarantee when gloves are part of a managed service with controlled washing and testing, rather than informal reuse at operator level.

How often should ESD gloves be tested?

There is no single rule that fits every plant, but ESD gloves should be tested regularly enough that you can be confident they still meet your ESD program requirements. Many facilities test by batch, by number of wash cycles, or at fixed intervals such as monthly or quarterly, depending on risk and usage. When you use a rental or service model, the provider builds this testing into the process and removes any gloves that fail.

Do ESD gloves also help with contamination control?

Yes, cleanroom esd gloves are designed to combine static control with low particle and fiber release. They help reduce the risk of skin flakes, fibers and oils reaching your product or equipment. However, they only work as part of a full cleanroom and garment system that includes suitable coveralls, masks and other garments. A professional service helps you design this system as a whole, not glove by glove.

Can I wash ESD gloves at home or in a normal laundry?

Washing ESD gloves at home or in a normal industrial laundry is risky. Detergents, softeners and uncontrolled temperatures can change the glove’s surface resistance and damage coatings, which means they may no longer be ESD safe. To keep performance consistent, ESD gloves should be washed in a controlled process with tested recipes and documented parameters. This is one of the main reasons many Indian manufacturers choose a specialist glove and garment service.

Which ESD glove materials are best for electronics work?

For most electronics and assembly work, thin knitted gloves made from nylon or polyester with carbon fibers and a PU-coated fingertip or palm are a good starting point. They offer a good balance of static control, dexterity and comfort, and are widely used in IEC 61340-5-1 compliant gloves. For tasks that involve chemicals or higher mechanical loads, different materials may be needed. We usually recommend running a short on-site trial to see which option works best for your team and processes.

Are ESD gloves required in cleanrooms?

Yes, in many cleanroom and electronics environments, ESD gloves are mandatory to meet contamination control and ESD compliance requirements.

Are nitrile gloves ESD safe?

Standard nitrile gloves are not ESD safe. Only conductive or ESD-certified nitrile gloves provide controlled static dissipation.

What standards apply to ESD gloves in India?

Most Indian pharma, electronics and device manufacturers refer to international ESD standards such as IEC 61340-5-1 for protection of electronic devices from electrostatic phenomena. Auditors may also look at how your ESD gloves fit into your wider ESD control program, including flooring, clothing, wrist straps and training.