ESD Cap in India: small headwear, big impact on hair and static

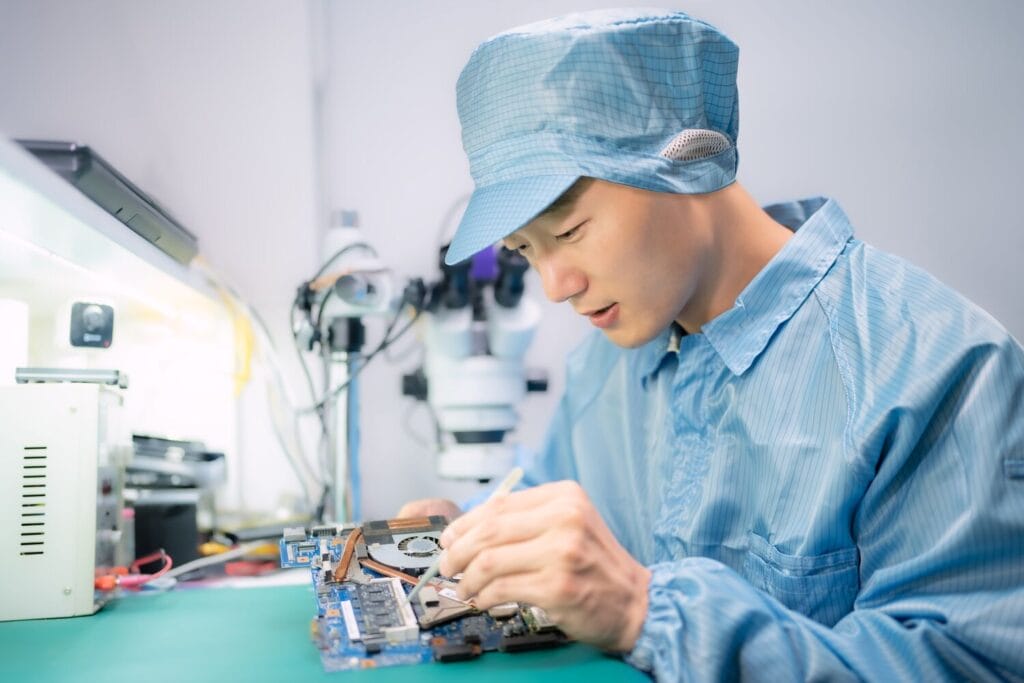

Hair and scalp are two of the biggest particle generators on any production floor. They shed skin flakes and hairs all day. At the same time, normal hair and fabric around the head are good at building up static charge.

An esd cap gives you a simple way to control both problems. It is part of your cleanroom esd headwear system and sits between the operator’s head and your sensitive products. In Indian pharma, diagnostics and electronics plants, this small piece of clothing can make the difference between a stable process and constant nuisance issues.

In this blog, we will explore what an ESD cap is, how it differs from a normal hairnet or bouffant, what can go wrong if you ignore headwear, how to choose the right design.

What is an ESD cap and how does it work?

An esd cap is a piece of headwear made from static dissipative, low-lint fabric. It is designed to do two jobs at the same time:

- Control static on and around the head

- Capture hair and particles from the scalp and hair

Typical ESD caps use polyester or similar synthetic fabric with conductive fibres woven in a grid pattern. These fine carbon or metal fibres carry charge away in a controlled way instead of letting it build up and jump as a discharge. The ESD cap usually connects electrically to the rest of the ESD garment system, for example through contact with the ESD coat at the neck.

ESD cap vs. Disposable bouffant cap:

Many Indian facilities still use simple disposable bouffant caps or hairnets. These help with basic hair contamination control, but they do very little for static. They are often made from nonwoven polypropylene that can actually charge up quite easily.

Key differences:

- Material: An ESD cap uses static dissipative, low-lint fabric. A disposable cap focuses only on covering hair and is normally not ESD controlled.

- Durability: An ESD cap is reusable and designed for many wash cycles. A bouffant cap is single use.

- Role in ESD programme: An esd cap India can be tested and documented as part of your ESD control plan. A normal hairnet is just hygiene PPE.

If your process involves sensitive electronics or diagnostics equipment, a normal hairnet is not enough for ESD control.

ESD cap vs. Antistatic cap:

You may also see the term antistatic cap. In practice, this usually means a cap that reduces static build up compared with normal fabric, but it may not be part of a fully tested ESD garment system.

When you buy for serious ESD control, the important questions are:

- Has the fabric been tested for surface or point-to-point resistance?

- Does the supplier reference ESD garment standards, for example IEC 61340 for static control clothing?

- Is the cap designed to work with ESD coats and other garments?

If the answer is “no idea”, treat it as a basic antistatic cap, not a true ESD cap.

What can go wrong without proper ESD caps?

If you miss the head in your ESD and gowning concept, you leave a major source of particles and static uncontrolled. Problems may not show up as spectacular failures. They creep in as “little annoyances” that slowly eat performance.

Risks in electronics manufacturing and test:

Imagine an SMT or module assembly line that takes ESD seriously. You install ESD flooring, shoes and coats. You use wrist straps at benches. Then you let people walk in with normal hairnets or uncovered hair near open boards.

This can lead to:

- Micro-damage to PCBs and components: Static builds up on hair and scalp. When an operator leans over a powered board or reaches into a test jig, discharge can occur. Most events are not visible or felt. They show up later as latent defects.

- Nuisance failures in sensitive devices: Devices pass end-of-line test but then fail under field conditions. Investigations often point to “ESD suspected”, yet all the obvious controls are in place. Missing ESD headwear is an easy blind spot.

- Quality and customer complaints: Frequent RMAs, erratic test failures, or noisy measurements in labs all add cost and damage your reputation.

Risks in diagnostics and pharma cleanrooms:

In diagnostics assembly, biotech and pharma cleanrooms, hair and scalp are huge contributors to bio and particle load.

Without proper cleanroom hood and cap combinations, you may see:

- Hair contamination control failures: Loose hair, dandruff and skin flakes can reach open vials, syringes or diagnostic cartridges, even when people “tie hair properly”.

- Visible hairs in product: One hair inside a transparent device, vial or primary pack is enough for a batch rejection or a serious complaint.

- Audit findings: Regulators and customer auditors look more closely now at gowning, including headwear, as part of a contamination control strategy driven by GMP and Annex 1. Weak arguments like “simple caps are enough” are getting harder to defend.

Real-life patterns in Indian sites:

Some typical patterns we see:

- Mixed use of cloth caps, disposable hairnets and bare heads in the same controlled area.

- No clear rule on beard covers, sideburns and long hair.

- Use of ESD coats and footwear in an EPA, but only basic hairnets with no static control.

- Operators adjusting loose disposable caps during work, which releases more particles over the product.

All of this can be improved with a simple, consistent ESD cap policy and the right garments to back it up.

How to choose the right ESD cap for your cleanroom in India?

Choosing an esd cap is about coverage, fabric, comfort and fit with the rest of your PPE. Here is a practical checklist you can use.

1. Decide on cap type and coverage:

Different environments need different cleanroom esd headwear options.

Common styles:

- Skull cap: Covers the crown and sides of the head. Suitable for lower risk areas or where a full hood is not practical.

- Peaked ESD cap: Similar to a baseball cap, often combined with an ESD coat. The peak helps shield products from particles when people lean forward.

- Full hood: Covers head, sides, neck and sometimes shoulders. Often used in higher cleanroom grades or where strict hair contamination control is needed.

Questions to ask:

- How strict is your hair contamination control requirement in this area?

- Do you have facial hair or long hair to control?

- Do you already use a cleanroom hood and cap combination and just need to update to ESD fabric?

In many Indian sites, a mix makes sense. Skull or peaked caps in support areas and test labs. Full hoods in main cleanrooms.

2. Check fabric and ESD performance:

Look closely at the fabric:

- It should use low-lint synthetic yarns with a conductive grid or fibres.

- Ask for ESD garment test data in line with standards such as IEC 61340, not just a marketing claim.

- Confirm that ESD performance remains within range after repeated laundering.

For pharma and higher cleanroom grades, make sure the same fabric also meets your cleanliness and particle limits.

3. Consider compatibility with other PPE:

Your ESD cap has to live with other PPE on the head and face:

- Goggles and spectacles: Make sure the cap or hood does not push goggles away from the face or interfere with seals.

- Masks and respirators: Check that straps do not conflict with cap elastic and that operators can don in a consistent order.

- Helmets: In some industrial electronics or battery plants, people wear helmets. In this case, a thin skull cap or liner that fits comfortably under the helmet is usually needed.

- ESD shoes: Ensure the cap fits into the overall ESD garment system—including coats, gloves and ESD shoes so the full head-to-toe grounding pathway remains consistent across all operator movements.

A short trial in real workstations is the best test. If people struggle, they will improvise, and that is rarely good for ESD or hygiene.

4. Match to cleanroom grade and zoning:

For Indian cleanroom facilities, headwear should follow your zoning:

- In higher grades, for example ISO Class 5 / Grade A and B, full hoods that connect to coveralls are often expected.

- In lower grades such as ISO 7–8 / Grade C and D, an ESD cap with coat and mask may be enough, depending on product risk and your contamination control strategy.

- Write this clearly into your SOPs so there is no confusion about when to use which option.

This is also where a standardised esd cap India policy across multiple sites helps a lot. Your QA and operations managers can speak the same language.

5. Comfort and fit in hot and humid climates:

Headwear can quickly become uncomfortable in warm and humid Indian conditions. If caps feel suffocating or tight, people will pull them back or leave hair exposed.

Look for:

- Light, breathable low-lint fabrics instead of very heavy cloth.

- Adjustable closures or elastic that is firm but not painful around the forehead.

- Patterns and sizes that fit both smaller and larger head sizes without gaps.

Run pilots on real shifts, not just a five minute wear test in a meeting room. Long-term comfort matters.

6. Lifecycle cost and sustainability:

Even small items like caps add up:

- Reusable ESD caps cost more per piece than hairnets, but you can use them for many cycles if properly washed and inspected.

- When you factor in product risk, audit findings and waste, a reusable, well managed solution can be more cost effective and sustainable than high volumes of disposables.

- A rental model spreads cost over time and take away the guesswork of how many caps to buy and when to replace them.

Gowning sequences: Where the ESD cap fits:

An ESD cap needs to be part of a clear gowning sequence. This helps reduce human-borne contamination and keeps static under control from the start.

A simple sequence for many EPAs and cleanrooms in India looks like this:

- Enter pre-gowning area, remove jewellery as defined and check personal grooming.

- Put on base garments if required, such as scrubs.

- Put on ESD or cleanroom shoes or boots.

- Put on the esd cap or hood, making sure all hair is inside.

- Put on mask and goggles in the correct order for your SOP.

- Put on ESD coat or coverall, ensuring cap and garment connect neatly around the neck.

- Use wrist strap if required at benches.

- Perform final mirror check before entering the controlled area.

The order is important. If you put the cap on too late, you risk loose hair and particles falling while you are already in the clean zone. If you put it on too early, then handle a lot of other personal items, you can contaminate the outside of the cap.

Short refresher trainings and clear visual instructions in gowning rooms make this much easier for your teams.

Maintenance, laundering and lifecycle management:

Like any ESD garment, an esd cap only delivers what it promises if it is washed and handled correctly.

Laundry and ESD performance:

Washing ESD caps with normal laundry can:

- Damage conductive fibers in the fabric.

- Leave residues from detergent or softener that change the surface resistance.

- Introduce lint and fibers from cotton garments back onto cap surfaces.

A controlled process for cleanroom esd headwear should have:

- Dedicated wash recipes for ESD and cleanroom garments.

- No fabric softeners that leave insulating films.

- Controlled drying temperatures to protect elastic and fabric.

- Separation of clean and dirty flows to avoid recontamination.

This can be done in-house if you have the right equipment and expertise, but in many Indian plants it is more practical to work with a specialist.

Inspections and tracking:

You need basic rules for when to remove caps from service:

- Visual checks for tears, worn elastic, heavy stains or damage around seams.

- Clear limits for maximum number of wash cycles or time in use, depending on fabric and risk level.

- Spot ESD testing on sample caps to confirm they still meet the required resistance range.

Simple identification labels and tracking tags help you know how long a cap has been in circulation.

Rental model vs owning your own caps:

If you manage caps in-house, you take care of:

- Buying stock and keeping buffer quantities

- Washing, drying and storing

- Replacing worn caps and disposing of them responsibly

With a rental or service model:

- You receive clean, tested caps in the right sizes and quantities at agreed intervals.

- Used caps are collected, washed, inspected and returned.

- Garments that reach end of life are removed and replaced automatically.

This gives more predictable cost, less waste and fewer surprises at audit time.

How Lindström supports your ESD cap and headwear system?

At Lindström India, we help electronics, diagnostics and pharma customers build practical, compliant head-to-toe solutions. ESD caps and cleanroom esd headwear are a natural part of that package.

Correct specification and selection:

We start with your process:

- What products do you handle?

- Which cleanroom grades or controlled areas do you have?

- What are your ESD control targets and hair contamination control expectations?

Based on this, we help you choose between skull caps, peaked caps and full hoods. We also align fabrics and colours with your wider garment system, so operators get a coherent, easy to understand set of rules.

Validated washing and decontamination:

Your caps are processed in our specialized laundries:

- Wash programmes are designed for ESD and cleanroom fabrics.

- We avoid chemicals that harm ESD performance.

- We follow procedures that protect the low-lint properties of the fabric.

This gives you a documented, repeatable process instead of ad hoc washing.

Repairs, replacements and inventory management:

We manage the lifecycle for you:

- Remove damaged or out-of-spec caps from circulation.

- Repair where it is safe and sensible to do so.

- Keep the right mix of sizes and styles available for your shifts.

If your headcount or layout changes, we adjust quantities and supply patterns with you.

Compliance and documentation:

Finally, we support your QA, EHS and engineering teams with:

- Technical data and garment descriptions for your SOPs.

- Evidence of washing, handling and replacement routines.

- Support during customer or regulatory audits when questions on garments and ESD caps come up.

You stay in control of your process, while we take care of the textile details in the background.

Conclusion:

An esd cap looks like a small accessory, but it plays a big role in hair contamination control and static management in Indian cleanrooms and electronics plants. When you choose the right style and fabric, match it to your cleanroom grades, and fit it into a clear gowning sequence, you close one of the biggest gaps in many ESD and hygiene programs.

With proper laundering, inspection and tracking, ESD caps keep doing their job quietly in the background. When they are part of a managed rental service, your team spends less time chasing missing headwear and more time keeping production stable.

Frequently Asked Questions:

Is an ESD cap always required in a cleanroom?

Not in every single room, but in any area where hair and static could affect sensitive products, an ESD cap or hood is strongly recommended. Higher grade cleanrooms and electronics EPAs almost always require controlled headwear. Your contamination control strategy and ESD risk assessment should define exactly where they are mandatory.

What is the difference between an ESD cap and a normal hairnet?

A normal hairnet or disposable bouffant focuses only on covering hair for basic hygiene. An ESD cap uses special fabric that helps control static and sheds fewer particles, and it is designed to connect with other ESD garments. If you handle sensitive electronics or diagnostics devices, a normal hairnet is not enough on its own.

Do ESD caps need to be grounded separately?

In most systems, ESD caps are not grounded with a separate wire. Instead, they are designed to touch ESD coats or coveralls, which in turn connect to the operator and the ESD footwear and floor. The cap is one part of this path. This is why good fit and correct gowning order are important.

Can ESD caps be washed with normal laundry?

They should not be washed with normal laundry. Regular detergents, softeners and mixed loads can damage conductive fibers or leave residues that change surface resistance. ESD caps need controlled washing with defined recipes, separate from general workwear. A professional garment service will include this as standard.

Which type of ESD cap is best for my process?

They can, but it is not always ideal. Using ESD shoes everywhere may increase wear and contamination, which can change resistance over time. In some plants, it makes sense to limit them to EPAs and nearby support areas and use other footwear elsewhere. If operators need to move between many zones, a clear zoning and cleaning concept helps avoid mistakes.

What is the best ESD headwear option for my cleanroom or lab?

There is no single best option. Skull caps or peaked caps can be enough in labs, support areas and some assembly lines. Full hoods are usually better in higher grade cleanrooms or where hair contamination control is critical. The right answer depends on your product, cleanroom grade and other PPE, so it is worth reviewing this with your ESD and QA teams or with a specialist partner.

Are there ESD caps suitable for pharma environments?

Yes. There are ESD caps and hoods made from cleanroom-grade, low-lint fabrics that suit pharma, biotech and diagnostics facilities. They help you manage both static and hair contamination without adding particle load.