The Different Cleanroom Classifications and Areas

In pharmaceutical manufacturing, maintaining the proper level of cleanliness is not just good practice; it’s a critical requirement that directly impacts product quality, safety, and regulatory compliance. Cleanrooms serve as controlled environments where airborne particulates, microorganisms, and other contaminants are strictly managed to protect sensitive manufacturing processes. Understanding the various cleanroom classifications is essential for pharmaceutical professionals who need to design, operate, and maintain these specialized environments. This comprehensive guide explores the different cleanroom classifications and areas, their specific requirements, and how they impact pharmaceutical operations in today’s highly regulated industry.

What are cleanroom classifications?

Cleanroom classifications are standardized systems that define the maximum allowable limits of airborne particles within controlled environments. These classifications provide a framework for designing, constructing, and operating spaces where contamination control is critical to product integrity. For pharmaceutical manufacturers, adherence to these classifications is not optional but a fundamental requirement for regulatory compliance and product safety.

Two primary classification systems govern cleanroom environments globally:

- ISO 14644 (International Organization for Standardization) – A globally recognized standard that classifies cleanrooms based on airborne particulate cleanliness

- EU GMP (European Union Good Manufacturing Practice) Annex 1 – Specific guidelines for sterile medicinal product manufacturing that categorizes cleanrooms into grades A through D

Pharmaceutical manufacturers must navigate these classification systems to ensure their facilities meet the stringent requirements for producing safe, effective medications. The classification selected for a particular area depends on the sensitivity of the processes being performed, with more critical operations requiring higher levels of cleanliness and contamination control.

ISO 14644 classifications explained:

The ISO 14644 standard provides a comprehensive framework for cleanroom classification based on the concentration of airborne particles. This system ranges from ISO Class 1 (the cleanest) to ISO Class 9 (the least clean), though pharmaceutical manufacturing typically utilizes ISO Classes 5 through 8, with particular focus on ISO Class 5 vs ISO Class 6 Cleanrooms for critical operations and background environments.

| ISO Classification | Maximum particles/m³ ≥0.5μm | Typical Applications |

|---|---|---|

| ISO 5 | 3,520 | Aseptic filling, sterile product manufacturing |

| ISO 6 | 35,200 | Background environment for ISO 5, component preparation |

| ISO 7 | 352,000 | Non-sterile manufacturing, packaging of sensitive products |

| ISO 8 | 3,520,000 | General pharmaceutical manufacturing, secondary packaging |

The ISO class 7 cleanroom represents a mid-range environment commonly used in pharmaceutical manufacturing for processes that require significant contamination control but do not involve directly exposed sterile products. These areas typically require 30-60 air changes per hour and maintain positive pressure differentials relative to surrounding areas of lower classification.

For pharmaceutical manufacturers, the ISO classification directly influences several operational factors:

- Air filtration requirements (typically HEPA filters with 99.97% efficiency at 0.3μm)

- Air change rates and airflow patterns

- Environmental monitoring frequency

- Cleaning protocols and validation requirements

- Personnel gowning procedures

Each ISO class comes with specific design requirements that impact construction materials, surface finishes, and mechanical systems. These requirements ensure the environment can be maintained at the appropriate cleanliness level during routine operations.

EU GMP Annex 1 cleanroom grades

While ISO standards are used globally, pharmaceutical manufacturers in many regions also adhere to the EU GMP Annex 1 guidelines, which categorize cleanrooms into four distinct grades (A through D). These grades correlate with specific pharmaceutical manufacturing activities and have their own set of requirements.

| EU GMP Grade | ISO Equivalent | Typical Application | Maximum Permitted Particles/m³ ≥0.5μm (at rest) |

|---|---|---|---|

| Grade A | ISO 5 | Aseptic operations, filling, open ampoules/vials | 3,520 |

| Grade B | ISO 5/6 | Background environment for Grade A zones | 3,520 |

| Grade C | ISO 7 | Preparation of materials for filling, less critical stages | 352,000 |

| Grade D | ISO 8 | Component preparation, bulk handling of materials | 3,520,000 |

A key distinction of the EU GMP system is its focus on both microbial contamination and particulate matter. Unlike ISO standards that primarily address particle counts, EU GMP includes specific limits for viable organisms (bacteria, fungi, etc.) that are particularly relevant for pharmaceutical production.

Grade A areas, representing the highest level of cleanliness, are typically implemented as laminar airflow workstations or isolators where critical aseptic operations occur. These zones require unidirectional airflow and rigorous environmental monitoring to ensure product sterility is maintained throughout manufacturing processes.

Pharmaceutical manufacturers must establish clear transitions between different grade areas, with appropriate pressure cascades, airlocks, and gowning protocols to prevent cross-contamination as personnel and materials move between zones.

How do cleanroom requirements affect operations?

The classification of a cleanroom significantly impacts daily pharmaceutical operations across multiple dimensions. Understanding these operational implications is essential for maintaining compliance while optimizing productivity.

Air pressure and flow management:

Cleanrooms operate on a principle of pressure differentials between adjacent areas. Higher classification areas maintain positive pressure relative to surrounding spaces of lower classification. This pressure cascade prevents the inward flow of contaminants when doors are opened or personnel transition between areas.

Typical pressure differentials range from 10-15 Pascals between adjacent zones, requiring sophisticated building management systems to monitor and maintain these critical parameters. Any deviation from established pressure requirements can compromise the controlled environment and potentially affect product quality.

Environmental monitoring requirements

Each classification level comes with specific monitoring requirements that increase in frequency and scope with higher cleanliness levels:

- Grade A/ISO 5: Continuous particle monitoring during operations, frequent microbiological sampling

- Grade B/ISO 6: Daily particle counts, weekly microbiological sampling

- Grade C/ISO 7: Weekly particle counts and microbiological sampling

- Grade D/ISO 8: Monthly particle counts and microbiological sampling

These monitoring activities generate substantial data that must be analyzed, documented, and retained as part of the facility’s quality management system. Any out-of-specification results require investigation and corrective actions, potentially impacting production schedules.

Cleaning and disinfection protocols:

Cleaning protocols become progressively more stringent with higher classifications. Grade A/ISO 5 environments typically require daily cleaning with rotational use of different disinfectants to prevent microbial resistance. Lower classification areas may have less frequent cleaning schedules but still require validated procedures and documented execution.

All cleaning agents must be qualified for use in pharmaceutical environments, with residue testing and efficacy validation against relevant microorganisms. The cleaning process itself must be performed by trained personnel following detailed standard operating procedures to ensure consistency and effectiveness.

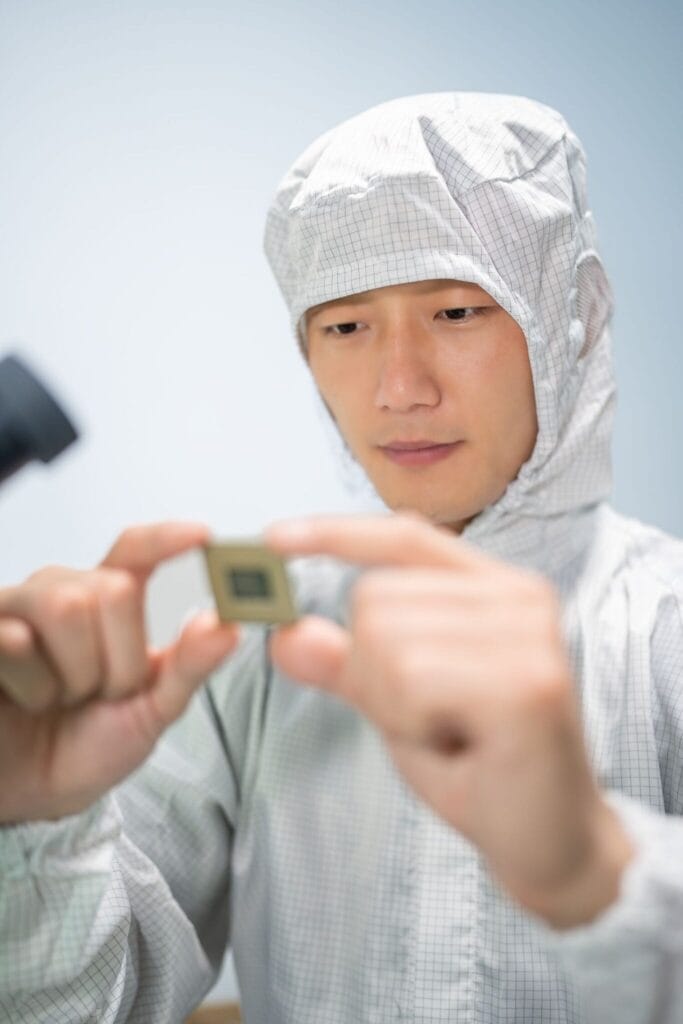

Cleanroom garment requirements by classification:

The level of personnel gowning directly correlates with cleanroom classification, becoming more comprehensive as the classification level increases. Proper garment selection and gowning procedures are essential for controlling human-generated contamination, which is often the primary source of particles in controlled environments.

Grade A/ISO 5 gowning requirements:

For the most critical environments, personnel require complete sterile coverage including:

- Sterile coveralls made from low-particle-shedding materials (typically polyester or polyester-blend fabrics)

- Sterile hood covering all facial hair and ears

- Sterile face mask and goggles or face shield

- Sterile gloves (often double-gloved)

- Sterile boot covers or dedicated cleanroom boots

These garments must be sterilized using validated processes and packaged to maintain sterility until use. Personnel working in Grade A environments typically dress in Grade B areas following a precise gowning sequence designed to minimize contamination.

Grade C/ISO 7 gowning requirements:

The ISO class 7 cleanroom requires substantial but less rigorous gowning than Grade A/B areas:

- Clean (not necessarily sterile) coveralls

- Hair cover

- Face mask

- Gloves

- Shoe covers or dedicated cleanroom shoes

While these garments don’t require sterilization, they must be laundered in controlled environments using validated processes that minimize particulate and microbial contamination. Many pharmaceutical manufacturers rely on specialized cleanroom garment service providers to ensure consistent quality and cleanliness of these critical items.

Grade D/ISO 8 gowning requirements:

The lowest classification typically used in pharmaceutical manufacturing requires basic protection that includes:

- Lab coat or gown

- Hair cover

- Optional face mask (process dependent)

- Shoe covers

Even at this level, garments must be suitable for cleanroom use, with minimal linting and appropriate durability to withstand repeated laundering without degradation.

Common challenges in cleanroom compliance:

Maintaining cleanroom compliance presents several ongoing challenges for pharmaceutical manufacturers, requiring vigilance and continuous improvement.

Personnel training and behavior:

Human activity remains the primary contamination source in most cleanrooms. Comprehensive training programs are essential to ensure all personnel understand how their movements and behaviors impact the controlled environment.

This training must cover:

- Proper gowning and de-gowning procedures

- Appropriate movement patterns within the cleanroom

- Material transfer protocols

- Response to deviations or excursions

Even with thorough training, maintaining consistent compliance requires regular refresher sessions and performance monitoring. Many facilities implement behavior observation programs to identify and correct potential issues before they impact product quality.

Documentation and regulatory requirements:

The documentation burden for cleanroom operations is substantial and includes:

- Environmental monitoring records

- Cleaning and disinfection logs

- Equipment calibration and maintenance records

- Personnel qualification and training documentation

- Change control for any modifications to the facility or processes

These records must be complete, accurate, and readily available for regulatory inspection. Many facilities now implement electronic documentation systems to streamline compliance efforts and improve data integrity.

Cost management:

Operating cleanroom environments entails significant costs beyond initial construction, including:

- Energy consumption (HVAC systems typically operate 24/7)

- Consumable items (garments, disinfectants, monitoring materials)

- Specialized cleaning services

- Environmental monitoring and testing

- Preventive maintenance of critical systems

Finding the balance between compliance requirements and operational efficiency remains an ongoing challenge for pharmaceutical manufacturers, particularly for smaller companies with limited resources.

Lindström’s specialized cleanroom solutions:

Specialized cleanroom textile services play a vital role in helping pharmaceutical manufacturers maintain compliance across different classification areas. These services address the unique requirements of each cleanroom grade while reducing the operational burden on manufacturing facilities.

Classification-specific garment programs:

Comprehensive cleanroom garment programs provide appropriate textile solutions for each classification level:

- Grade A/ISO 5: Sterile, low-particle-shedding garments with validated sterilization processes

- Grade B/C/ISO 6-7: Cleanroom-specific garments laundered in controlled environments

- Grade D/ISO 8: Basic cleanroom apparel with appropriate fabric specifications

These programs include regular garment inspection, repair, and replacement to ensure consistent performance and compliance with cleanliness requirements. The validated laundering processes ensure garments meet particulate and microbial specifications appropriate for their intended use environment.

Advanced tracking and inventory management:

Modern cleanroom textile services incorporate advanced tracking technologies to ensure garment traceability throughout their lifecycle.

These systems provide:

- Documented laundering history for each garment

- Usage tracking by classification area

- Automated inventory management to prevent shortages

- Quality assurance data for compliance documentation

This level of traceability supports pharmaceutical manufacturers in meeting the stringent documentation requirements of regulatory agencies while simplifying the management of cleanroom consumables.

Contamination control expertise:

Beyond providing garments, specialized cleanroom service providers offer valuable expertise in contamination control best practices, including:

- Gowning procedure optimization

- Garment selection based on specific process requirements

- Training support for cleanroom personnel

- Troubleshooting for contamination issues

This knowledge-sharing helps pharmaceutical manufacturers enhance their contamination control strategies and address potential compliance gaps before they become regulatory concerns.

By partnering with specialized cleanroom textile service providers, pharmaceutical manufacturers can focus on their core operations while ensuring their cleanroom garment programs maintain compliance with classification requirements and support overall quality objectives.

Conclusion:

Understanding the different cleanroom classifications and their specific requirements is fundamental for pharmaceutical manufacturers striving to maintain regulatory compliance and product quality. From the stringent controls of Grade A/ISO 5 environments to the more moderate requirements of Grade D/ISO 8 areas, each classification level presents unique operational considerations that impact everything from facility design to daily procedures.

By implementing appropriate contamination control strategies, including comprehensive cleanroom garment programs tailored to each classification level, pharmaceutical manufacturers can protect their products, comply with regulatory expectations, and optimize operational efficiency. Contact cleanroom service specialists to ensure your cleanroom textile program aligns with your specific classification requirements and supports your quality objectives.