Advancements in Cleanroom Suits Design for Optimal Sterility

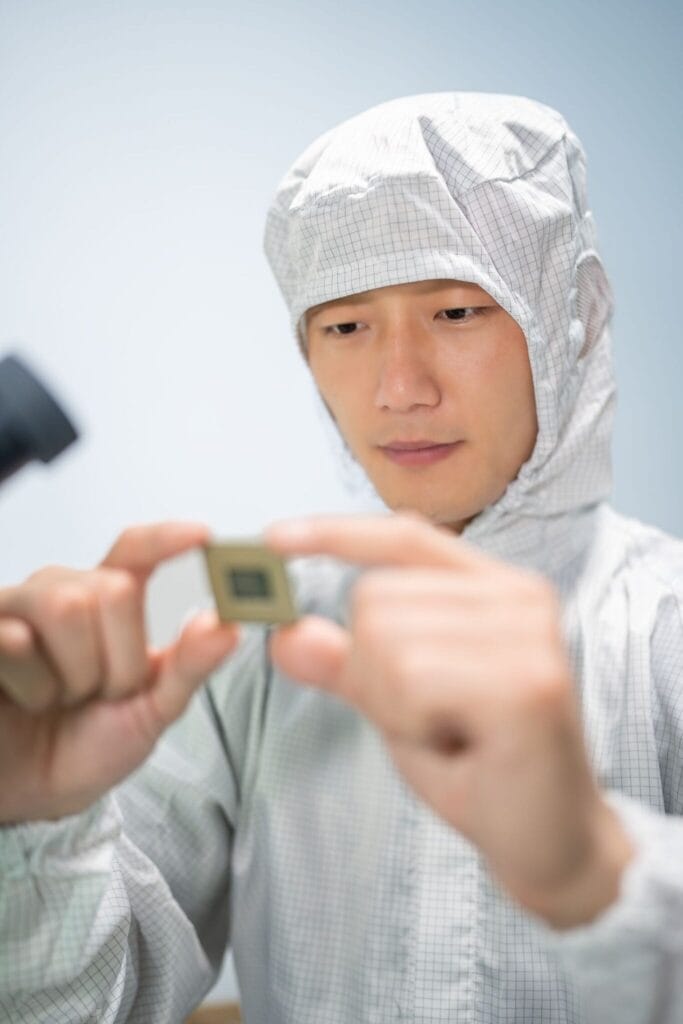

In India’s rapidly expanding pharmaceutical, biotechnology, and semiconductor sectors, cleanroom suits serve as the primary barrier against contamination, ensuring that critical manufacturing processes remain sterile. These garments—ranging from disposable coveralls and boot covers to reusable gowns, coats, and full-body suits with integrated hoods—prevent particles, microbes, and fibers generated by personnel from compromising product quality or regulatory compliance.

Key Drivers and Market Outlook in India:

The Indian cleanroom garment market is projected to grow at a CAGR of 8–10% over the next five years, fueled by:

- Growth of domestic and export‐oriented pharmaceutical manufacturing.

- Expansion of semiconductor fabs in Karnataka, Tamil Nadu, and Gujarat.

- Regulatory enforcement by CDSCO and alignment with ISO 14644 and EU GMP standards.

- Rising focus on cost‐effective, sustainable PPE solutions.

Material Innovations for Enhanced Sterility:

Antimicrobial and Bioactive Textiles:

Indian manufacturers are incorporating silver‐ion and copper‐ion treatments as well as photodynamic coatings into polyester and polypropylene blends. These fabrics achieve over 99.9% bacterial reduction while retaining breathability and comfort, even after 30+ industrial wash cycles.

Advanced Barrier Laminates:

Microporous laminates like DuPont™ Tyvek® and high‐density polyester with conductive ESD stripes are now available in India. These materials block particles down to 0.5 microns, resist fluid splashes, control electrostatic discharge, and meet ISO Class 4–5 requirements for critical cleanrooms.

Ergonomic Design and Seam Technology:

Comfort‐Focused Suits:

Modern suits feature adjustable neck closures, coordinated hat interfaces, ventilation panels, and articulated joints. These ergonomic enhancements reduce fatigue, improve mobility during 8–12 hour shifts, and minimise air‐flow disturbances that can lead to contamination.

Seamless Welding and Ultrasonic Sealing:

High‐frequency welding replaces stitched seams, creating continuous, particle‐impermeable barriers. Both disposable and reusable lines employ this technique, improving durability, fluid resistance, and integration with gloves, booties, and face shields.

Smart Technologies and Traceability:

Embedded Sensor Garments:

Indian cleanroom suppliers have begun integrating ultrathin silicone and printed conductive threads into suit fabrics to monitor motion, breathing rate, and perspiration in real time. Data is transmitted via Bluetooth to on‐site dashboards for compliance checks and ergonomic assessments.

RFID Tracking for Lifecycle Management:

RFID tags embedded in reusable coveralls and gowns allow manufacturing plants to track donning cycles, washing history, and sterilization status. Automated alerts notify quality teams when garments approach end‐of‐life, ensuring strict adherence to cleanroom protocols.

Regulatory Compliance and Sustainability:

- All garments comply with CDSCO guidelines, ISO 14644-5 for garment standards, and Indian Explosives Act where applicable.

- Biodegradable nonwoven fabrics and solvent‐free coatings reduce environmental impact and disposal costs.

- Local manufacturing in Mumbai, Chennai, and Hyderabad lowers lead times and import duties.

Conclusion:

As India’s life sciences and semiconductor industries scale up, investing in innovative cleanroom apparel is essential. Prioritize antimicrobial textiles, ergonomic designs, seamless construction, and smart traceability to maintain sterile conditions, enhance worker comfort, and optimise operational efficiency.

Frequently Asked Questions:

What fabric technologies ensure microbial control in Indian cleanrooms?

Silver‐ion and copper‐ion treated nonwoven blends, photodynamic coatings, and microporous polyethylene laminates deliver >99.9% bacterial reduction and meet ISO Class 4–5 requirements.

How do ergonomic features improve productivity?

Ventilation panels, adjustable hoods, moisture-wicking liners, and flexible joints reduce fatigue and airflow disruption, boosting operator performance during long shifts.

Which standards govern cleanroom garment use in India?

CDSCO, ISO 14644-5, EU GMP Annex 1, and local labour safety regulations define material, design, and lifecycle requirements for both disposable and reusable apparel.

What ISO class cleanroom garments are required for semiconductor fabs?

Semiconductor fabrication facilities typically require ISO Class 4–5 compliant ESD-safe cleanroom suits to prevent both particle contamination and electrostatic discharge damage.

How often should reusable cleanroom garments be replaced?

Replacement depends on fabric integrity, wash cycles, and manufacturer guidelines. RFID tracking systems help monitor garment lifecycle and indicate when performance standards are no longer met.

What is ESD protection in cleanroom garments?

ESD protection prevents static buildup that can damage sensitive semiconductor components. ESD-safe cleanroom suits use conductive fibers woven into polyester fabric.

Can cleanroom garments be customized for different industries?

Yes. Cleanroom suits can be customized based on ISO class requirements, antimicrobial levels, ESD compliance, and ergonomic needs for pharmaceutical, biotech, electronics, or aerospace sectors.

What factors should companies consider when selecting a cleanroom garment supplier in India?

When choosing a cleanroom garment supplier in India, companies should evaluate ISO 14644 compliance, GMP alignment, ESD certification (if applicable), garment durability, antimicrobial fabric technology, and validated laundering processes. Additionally, suppliers offering RFID-based lifecycle tracking, local manufacturing support, and documented quality control systems provide better long-term compliance, cost efficiency, and audit readiness.