Get the best out of your ESD garments

As the PLI scheme takes traction in electronic industry, more and more companies are aiming for India. While the need for using ESD garments (also Footwear and ESD flooring) is widely understood, what is not understood clearly, is the way to maintain these garments so the ESD properties are not lost over a period.

Presently the method followed by most Indian Electronic manufacturers is to give one set of ESD garments (ESD Apron & ESD Cap) to the employee and getting the same washed by employee at his home. Washing the ESD garment at home creates a lot of challenges notable being loss of ESD Property (Measured as Resistivity or Conductivity under certain voltages, Test Standard EN/IEC 61340-5-1) quickly, in many cases as early as within 5 washes. The same is experienced even when using local laundry companies. Principle reasons for this is use of domestic detergents which contains Chlorine bleach and/or ionic softeners.

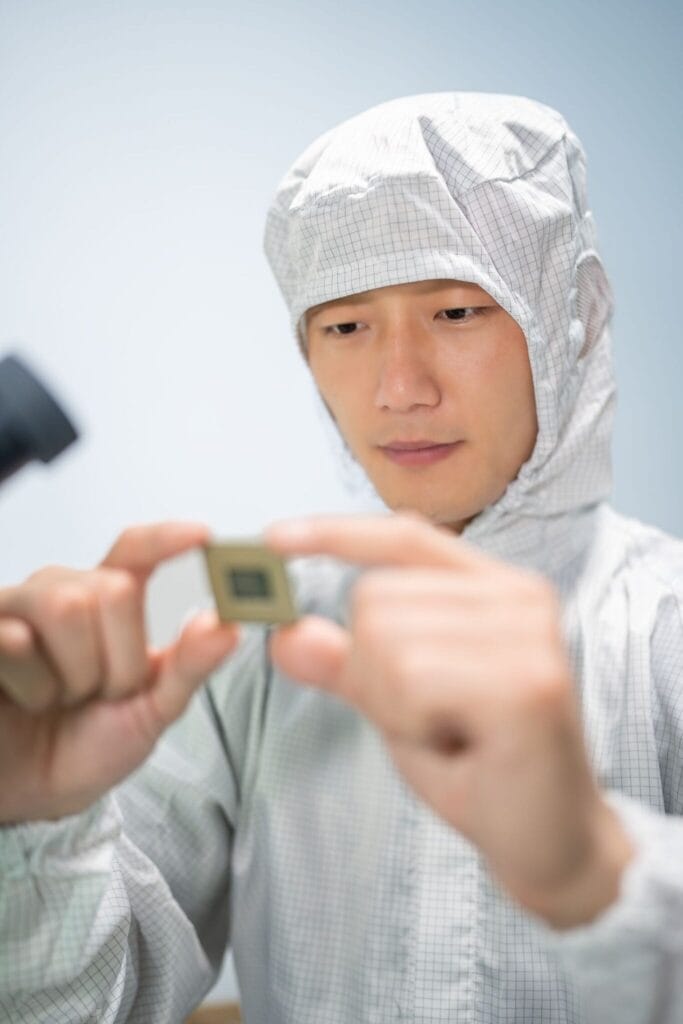

Built in a grid pattern, the black carbon threading woven into ESD safe clothing shields nearby electronics from static on your clothes and skin underneath. This threading is what gives ESD safe clothes their conductivity and what makes your ESD garment “static shielding”.

Chlorine bleach attacks carbon bonds which in turn destroys this black carbon threading.

Detergents also contain enzymes, bleaches, surfactants, and builders.

The surfactants found in many detergents include anionic (negatively charged) alkalis that interact with water to remove oily dirt and stains.

However, these can strip ESD Garments of their positive ions leaving them predisposed to carrying negative charges. Therefore, it is recommended to not use detergents when washing ESD Garments. But thanks to dusty Indian environment a lot of dirt and grime accumulates on the garment, especially on cuffs and collars.

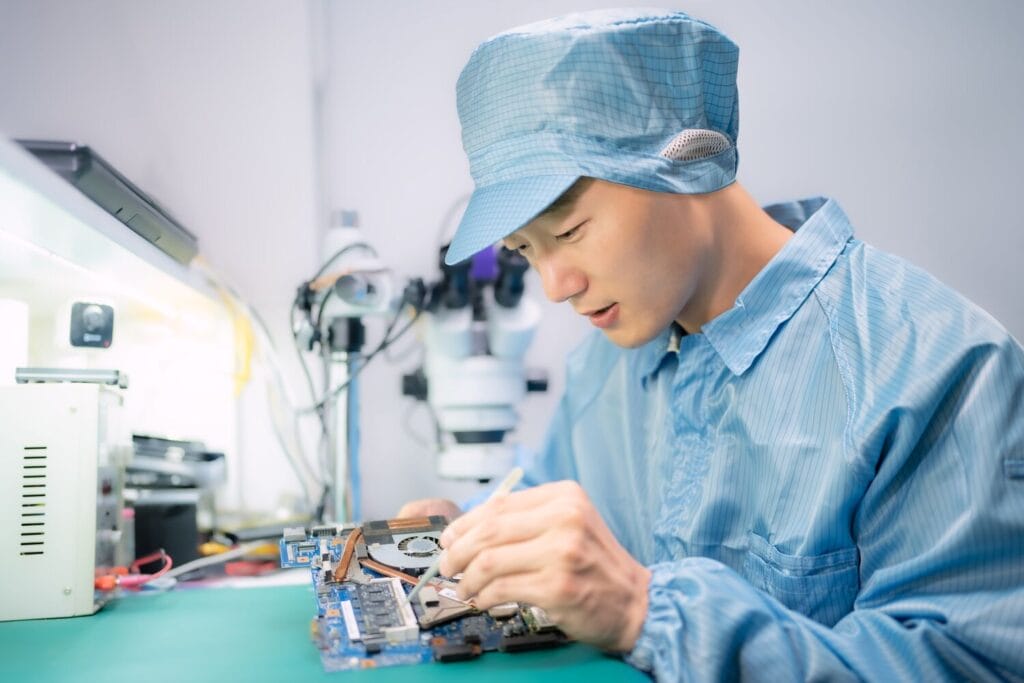

This is where specialized workwear management companies come into picture. They are specialists in managing this workwear and thereby ensuring that we can get about 100 washes from the ESD garments without it losing the ESD properties. Apart from this they have programable dryers which ensures that the garments are dried in low heat in a tumble dryer. This ensures that carbon in the garments are not altered during drying. Using high heat will alter the garment in a single wash itself and thereby making them lose their properties.

Frequently Asked Questions (FAQ)

Why is ESD garment maintenance of great importance?

ESD garments, if maintained properly, will retain their electrostatic discharge protective properties. Maintenance that is proper will ensure this protection here. Care that is improper can degrade those conductive fibers. For example, people might use domestic detergents along with chlorine bleach or ionic softeners, and this causes a loss of ESD protection after just a few washes.

What are the risks of washing ESD garments at home?

If you do wash ESD garments at your home, substances which degrade their protective properties may contaminate all of them. Detergents for domestic use often contain chemicals that can attack the carbon threading in a fabric because such chemicals reduce the ability of a garment to dissipate static electricity effectively.

How does professional laundering extend the life of ESD garments?

For the cleaning of ESD garments without damage occurring to conductive fibers, professional laundering services use specialized processes that do include programmable dryers with low heat settings. With this approach, approximately 100 washes become the garment’s effective lifespan.

What is the role of carbon threading in ESD garments?

Carbon threading woven into ESD garments creates a grid that dissipates static electricity, protecting sensitive electronic components. Damage to these threads, such as from improper washing, compromises the garment’s ESD protective capabilities.

Why should high heat be avoided when drying ESD garments?

High heat can alter the carbon within ESD garments because it degrades their conductive properties. Low heat settings, when used during drying, preserve the integrity of carbon threading, also the garment remains effective because of its dissipation of static charges.

Are there industry standards for ESD garment maintenance?

Yes, standards like EN/IEC 61340-5-1 outline requirements for ESD control garments, as well as they include maintenance practices. Clothes that follow these rules guarantee reliable static electricity safety.

How can companies ensure compliance with ESD garment protocols?

Partnering with specialized workwear management companies, such as Lindström, provides access to services that include proper laundering, maintenance, and replacement of ESD garments. This ensures ongoing compliance with ESD protection standards and safeguards sensitive electronic components.