Electronics and ESD: Effects of ESD

Electrostatic discharge, or ESD, affects electronic circuits and components. Some of these effects are immediate failures, while others may manifest weeks or years later. Electrostatic discharge (ESD) affects electronic components in several different ways. High static voltages that can infiltrate devices can damage their intricate internal circuitry. Due to MOS technology’s high input impedances, which prevent voltages from dissipating and allow for extremely high voltages to easily damage the small dimensions of both conductors and insulating barriers, the effects of ESD are now more apparent. Because integrated circuit feature sizes are getting smaller, electronics are becoming more susceptible to damage by static electricity.

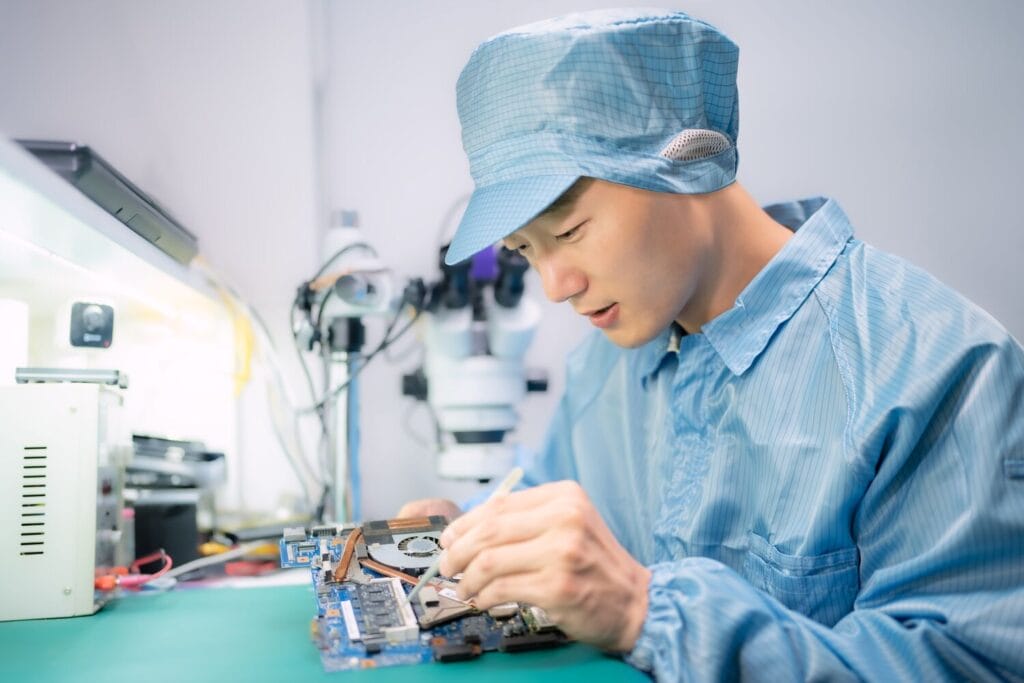

It is essential to examine the electronic devices themselves to see how they are impacted by ESD while examining how ESD affects electronic equipment.

Some electrical gadgets are discovered to be more susceptible to ESD than others. However, comparing the static charge levels to supply voltages is worth putting the issue in context. A logic gadget would not be subjected to even fifty volts of electricity. However, handling them without ESD safety measures can result in static voltages of several kilovolts being applied to them.

Devices with MOS – Metal Oxide Semiconductor – technology is typically the most susceptible to ESD. Due to their highly high impedances, these devices prevent the charge from dissipating in a more controlled manner. However, this does not imply that bipolar equipment is impervious to harm.

Static voltages as low as 250V can harm most CMOS devices. Due to their lower current consumption, these include the 74HC and 74HCT logic families, frequently employed in many systems that utilize “glue logic.” However, many new microprocessors and LSI circuits are highly susceptible to ESD and as less as 5 V supply voltage would render them useless, making them more vulnerable to ESD damage.

Logic devices are not the only electronics that must be protected from static electricity. Static voltages as low as 100V can kill RF GaAsFETs, making them particularly prone to damage. ESD also impacts numerous discrete FET variants. Again, MOSFETs are highly sensitive and commonly used in various RF applications.

Standard bipolar transistors can even be destroyed at potentials of roughly 500V. One excellent illustration of this is the newest transistors, which are predicted to have much lower internal geometries and offer higher operating frequencies. This merely serves as a broad illustration of a relatively tiny subset of ESD susceptibility levels. However, caution should be used when handling all semiconductor devices or SSDs.

These days, SSDs refer to more than just semiconductor devices. Even passive components are beginning to be classified as static sensitive in some regions. The push toward miniaturization has resulted in considerably smaller individual electronics components. They become more susceptible to the impacts of ESD damage as a result.

Mechanisms for electrostatic discharge:

Numerous factors influence how electrostatic discharge, or ESD, manifests its consequences. Most of these are challenging to measure. The amount of static that accumulates varies depending on the materials used, the day’s humidity, and even the size of the individual. Each individual can be termed as a capacitor that holds a charge. The typical person is equivalent to a 300 pF capacitor, though individual differences will drastically affect this value.

The discharge also differs in terms of how it happens. The charge will frequently dissipate quickly, usually in less than 100 nanoseconds. The peak current during this period may reach 20 or 30 amps. Numerous variables affect both the peak current and the discharge time. The current peak is higher and faster when a metal instrument, such as a pair of tweezers or thin-nosed pliers, is utilized instead of discharging through a finger. This is so because the metal offers the discharge a significantly lower resistance path. However the amount of charge dissipated remains independent of the discharge method.

Latent ESD damage:

A latent ESD damage happens in a device after the damage has been done to it while it is functioning. A failure later in the device’s life could result from this type of ESD damage. The fault can be stressed and eventually fail as a result of subsequent current surges brought simply by turning the equipment on or even by regular operation. In some circumstances, vibration may also be the cause of this.

These latent flaws are particularly concerning since they could result in equipment breakdowns later in life, lowering its reliability. In reality, facilities with inadequate anti-static protection are more likely to manufacture low-reliability equipment. According to estimates, at least ten devices have latent damage and will eventually fail for everyone that sustains immediate damage.

Latent ESD damage changes when large current pulses pass via metal-semiconductor contacts. The ensuing heating might be adequate to locally alloy silicon and aluminum. As a result, alloy spikes that can protrude horizontally or vertically from the contact pad may be created. Eventually, these could lead to shorts with nearby intersections.

Diffusion well corners in integrated circuits have also been particularly susceptible to latent ESD damage. This is what happens as a result of the field augmentation in these places.

ESD Examinations:

Although it is difficult to pinpoint why a device was destroyed, some specialized laboratories have the tools to carry out these studies. They remove the IC’s lid to expose the silicon chip inside. This is examined under a microscope to identify the damaged area.

These studies cost a fair amount of money. They are not typically taken on for everyday failures. Instead, they are only carried out when it’s imperative to ascertain the precise reason for the failure.

ESD is a significant issue for every business that produces electrical equipment. Static discharge damage can result in immediate component failure and latent faults that can present themselves later, significantly lowering the product’s overall reliability.

Frequently Asked Questions (FAQ)

Common ESD sources include human movement as well as handling of plastic materials also machinery that is ungrounded or even air movement when humidity is low. For instance, thousands of volts can be generated simply by the act of walking across a carpeted floor. If there is not proper management of everyday activities, static discharges may damage sensitive electronic components, most especially in semiconductor and in precision electronics environments.

Electronic devices can experience immediate failures also delayed failures from ESD. Sudden discharges might permanently destroy microchips also lower discharges can weaken circuits causing failure afterward. ESD is, because of that, a visible threat as well as a hidden one in electronics manufacturing.

Smaller circuits and thinner insulating layers used in modern electronic designs make them highly sensitive to voltage spikes. Technologies like MOS (Metal-Oxide-Semiconductor) are especially vulnerable due to their high input impedance and microscopic structure, which can be easily compromised by static discharge.

Latent defects happen if non-fatal ESD damage weakens a component’s performance or reliability. During quality control these defects are difficult to detect. Unexpected failure in the field often results in product recalls or warranty claims.

Preventive steps include grounding personnel with equipment, using ESD-safe flooring plus garments, humidity control, furthermore strict handling procedures are established. Education plus routine audits are also critical, so ESD safety practices are consistently followed.

ESD garments incorporate conductive fibers that prevent static accumulation on the wearer’s body. By neutralizing electrostatic charges, these garments reduce the risk of discharges when employees meet sensitive devices or circuit boards.

ESD control stays active at each critical point using an end-to-end approach since it includes packaging, transport, testing, and assembly. This thorough defense greatly reduces the chance that devices sustain obvious and unseen harm, so product dependability is higher, and customers feel pleased.