Navigating compliance: workwear standards & solutions

From preventing accidents to meeting legal requirements, businesses must ensure their employees are properly protected and following workwear standards. But with evolving regulations and industry-specific risks, staying compliant can feel like a moving target.

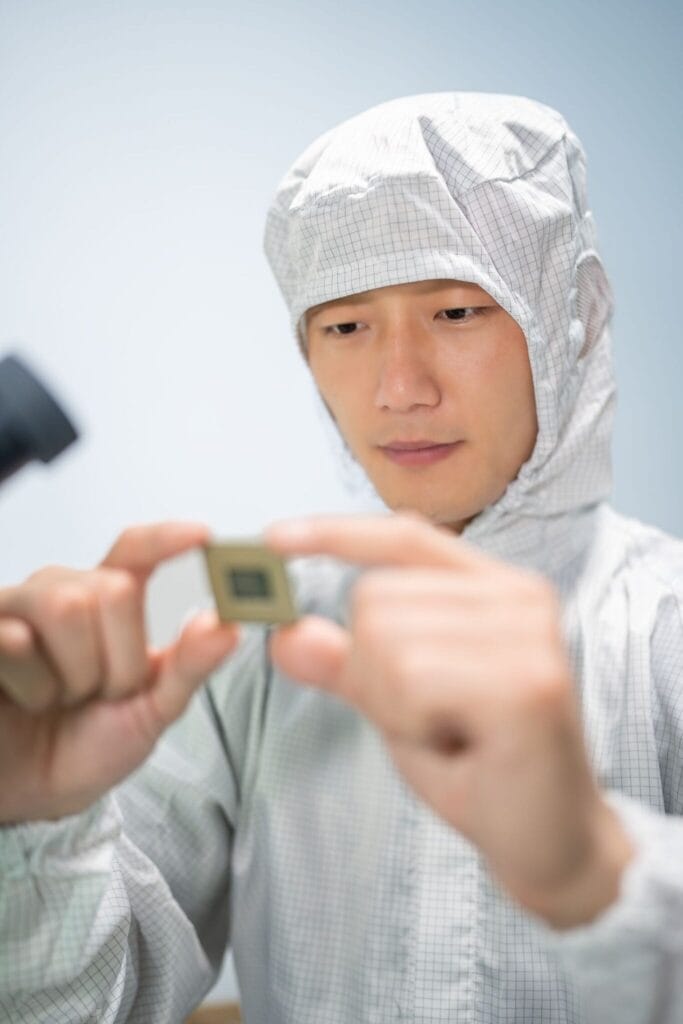

One key solution? Workwear that meets safety standards. Whether it’s high-visibility clothing for construction workers or hygienic garments for food processing, the right workwear plays a vital role in employee protection and operational efficiency.

In this article, we break down everything you need to know about workwear standards—what they are, how they work, common compliance challenges, and how Lindström makes it easy to stay on top of regulations.

What are workwear standards?

Workwear standards set the rules for protective clothing, ensuring it keeps employees safe in different industries. These standards cover everything from fabric choices to design features, making sure workwear protects against specific risks, such as chemicals, fire, or physical hazards.

For businesses, following these guidelines isn’t just about ticking boxes, but about reducing workplace risks, improving employee well-being, and ensuring compliance with industry regulations.

How do workwear standards work?

Standards outline key criteria for protective clothing, such as:

✔️ Material durability – Can it withstand heat, moisture, or chemicals?

✔️ Visibility – Is it designed to keep workers seen and safe?

✔️ Ergonomics – Does it provide comfort and functionality?

These regulations are set by industry bodies and regularly updated to keep up with new risks. Businesses must ensure their workwear meets these evolving standards through proper selection, testing, and certification.

Practical applications of workwear compliance

Staying compliant starts with identifying workplace hazards. Once risks are clear, businesses can select the right workwear solutions that meet safety requirements.

Examples of industry-specific compliance needs:

🔹 Construction & logistics – High-visibility clothing prevents accidents by ensuring workers are seen.

🔹 Food processing – Hygienic workwear helps prevent contamination, keeping food safe.

Choosing the right partner for workwear solutions makes compliance easier, so that you can focus on your core operations.

Common challenges in adhering to workwear standards

One of the primary challenges organizations face in adhering to workwear standards is staying updated with the ever-evolving regulations. Changes in industry practices, technology, and legislation can lead to amendments in standards, requiring organizations to continuously adapt. Additionally, the initial cost of implementing compliant workwear solutions can be a barrier for some businesses.

To overcome these challenges, organizations can invest in compliance solutions that offer regular updates and insights into changing standards. Partnering with experienced providers who specialize in compliant workwear can also alleviate the burden, ensuring that the organization remains up-to-date and compliant without incurring unnecessary costs.

How Lindström ensures compliance

Lindström, with extensive experience in the textile rental service industry, offers a comprehensive approach to workwear compliance. By providing end-to-end solutions, from designing to maintaining workwear, Lindström ensures that its products meet the highest safety standards. Our focus on sustainability and innovation allows us to offer workwear that is not only compliant but also aligns with the circular economy.

What sets us apart?

- Expert knowledge – We track industry regulations, so you don’t have to.

- Sustainable innovation – Our workwear is both compliant and incorporating circular economy practices.

- Seamless service – We handle everything from supply to laundry, repairs, and replacements.

Comparing workwear standards to alternative safety measures

While workwear standards are an essential component of workplace safety, they are not the sole measure organizations can implement. Other safety measures, such as engineering controls, administrative policies, and personal protective equipment (PPE), also play a significant role in ensuring a safe working environment.

Each safety measure has pros and cons. Workwear standards provide a consistent and reliable baseline of protection, while engineering controls can eliminate hazards at the source. Administrative policies and PPE offer additional layers of protection, each contributing to overall workplace safety. A comprehensive safety strategy often involves a combination of these measures, tailored to the specific needs and risks of the workplace.