How cleanroom validation works and why it matters

In industries where even the tiniest particle can cause serious damage, cleanroom validation ensures everything runs as it should. Whether it’s pharmaceuticals, biotech, or electronics, these controlled spaces must stay spotless. That’s where validation comes in.

Cleanroom validation confirms that your environment meets set standards for cleanliness, air quality, temperature, and other key conditions. More importantly, it ensures that those standards are consistently upheld over time. Without regular validation, compliance and quality assurance become guesswork, and that’s not good enough in critical sectors.

Quick summary: Why cleanroom validation matters

- Cleanroom validation ensures controlled environments meet international cleanliness standards.

- It includes testing air quality, calibrating equipment, and training staff.

- Proper validation protects product safety, supports compliance, and reduces contamination risk.

- Challenges include changing regulations, new technologies, and human error.

- Future trends like automation and smart tracking are improving validation outcomes.

What is Cleanroom Validation?

Cleanroom validation is a formal process that checks whether a cleanroom operates within its designed parameters. This means testing the air, equipment, surfaces, and procedures to verify that the space meets international standards like ISO 14644.

Validation is not a one-time event. It’s part of a regular cycle of checks and improvements, ensuring that cleanroom conditions remain under control even as people, processes, and equipment change. It makes sure your products, people, and customers stay safe.

What to validate, and why?

Several key components make up a validated cleanroom. Each must work perfectly on its own, but also function well together:

1. Environmental monitoring

This involves checking air quality and surface cleanliness. Cleanrooms use HEPA or ULPA filters to trap particles, but filters need monitoring and replacement to stay effective. Regular testing ensures particle levels stay within safe limits.

2. Equipment calibration

All devices—from air handling units to thermometers—must deliver accurate, reliable readings. Calibration confirms that equipment works as intended, reducing the risk of false alarms or missed contamination.

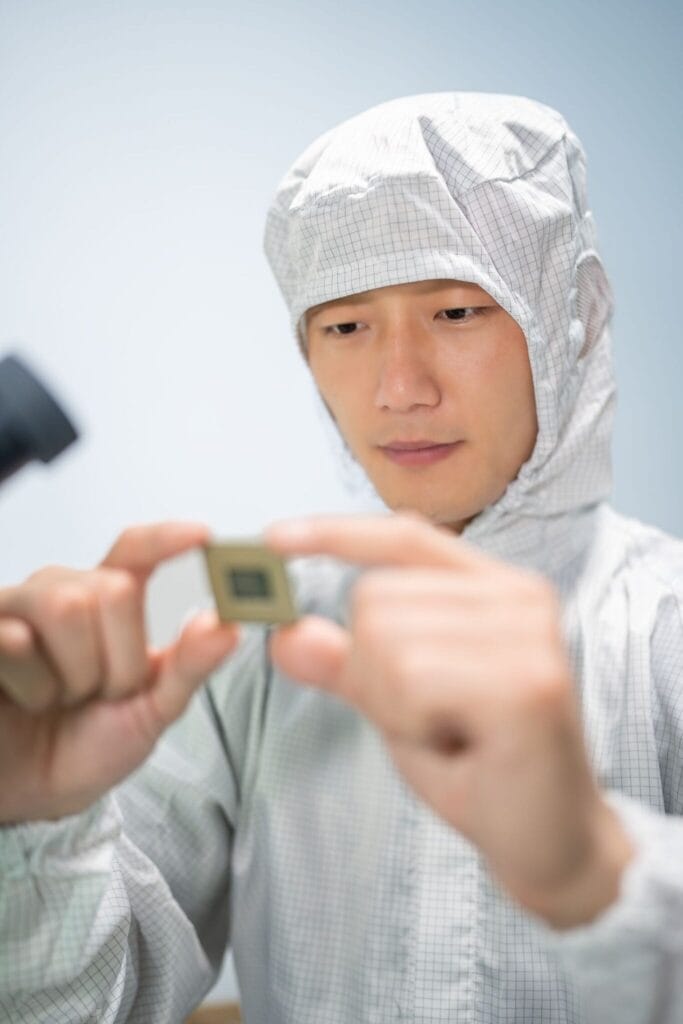

3. Staff training and behaviour

People can be the biggest contamination risk. Training staff on gowning, gloving, and behaviour in clean zones helps prevent costly mistakes. It also supports a culture of compliance, which strengthens the whole operation.

Together, these areas form the foundation of effective cleanroom validation. Ignore one, and the whole system can fall apart.

How validation supports quality assurance

Validation is a compliance requirement but also a quality assurance tool. It helps ensure that medicines are sterile, that microchips function without failure, and that production stays smooth and uninterrupted.

For example:

- In pharmaceuticals, poor validation can lead to contaminated products, regulatory fines, or patient safety risks.

- In electronics, a single dust particle can destroy a circuit and halt production.

Validation is a strategic choice to protect product quality, customer trust, and the reputation of your company.

What makes validation difficult?

Cleanroom validation isn’t always straightforward. Common challenges include:

- Changing regulations: Standards differ between industries and countries, and they change frequently.

- New technologies: Innovations in equipment or processes often require updated validation protocols.

- Human error: Even well-trained staff can forget procedures, skip steps, or handle equipment incorrectly.

Addressing these challenges means staying proactive. This might include regular training refreshers, investing in better monitoring systems, or building flexibility into validation schedules.

Future trends in cleanroom validation

Innovation is making cleanroom validation faster, smarter, and more sustainable.

- Automation and real-time monitoring: Sensors now offer instant feedback on air quality, humidity, and pressure, so teams can act before problems escalate.

- Smart garments and RFID tracking: These help manage cleanroom clothing more effectively, improving compliance and traceability.

- Predictive maintenance: IoT-connected systems can flag issues before they cause failures, reducing downtime and waste.

These advancements improve validation not just technically, but also in terms of cost, efficiency, and environmental impact.

FAQ – Common questions about cleanroom validation

What is cleanroom validation?

Cleanroom validation is the process of testing and confirming that a cleanroom meets defined cleanliness standards and operates consistently within controlled parameters.

How often should a cleanroom be validated?

This depends on your industry and risk profile. For pharmaceuticals, cleanrooms are typically validated at installation, after changes, and annually as a minimum. High-grade cleanrooms may require more frequent testing.

Which standards govern cleanroom validation?

The most widely used standard is ISO 14644, especially for air cleanliness classification. Pharmaceutical environments also follow EU GMP guidelines, including Annex 1.

What happens if validation fails?

You may need to stop production, investigate the cause, and take corrective action. Regulatory bodies may also require documentation or additional inspections.

How can I simplify the validation process?

Outsourcing cleanroom garment management, using automated monitoring systems, and training staff regularly are effective ways to reduce risk and improve efficiency.